Key Features

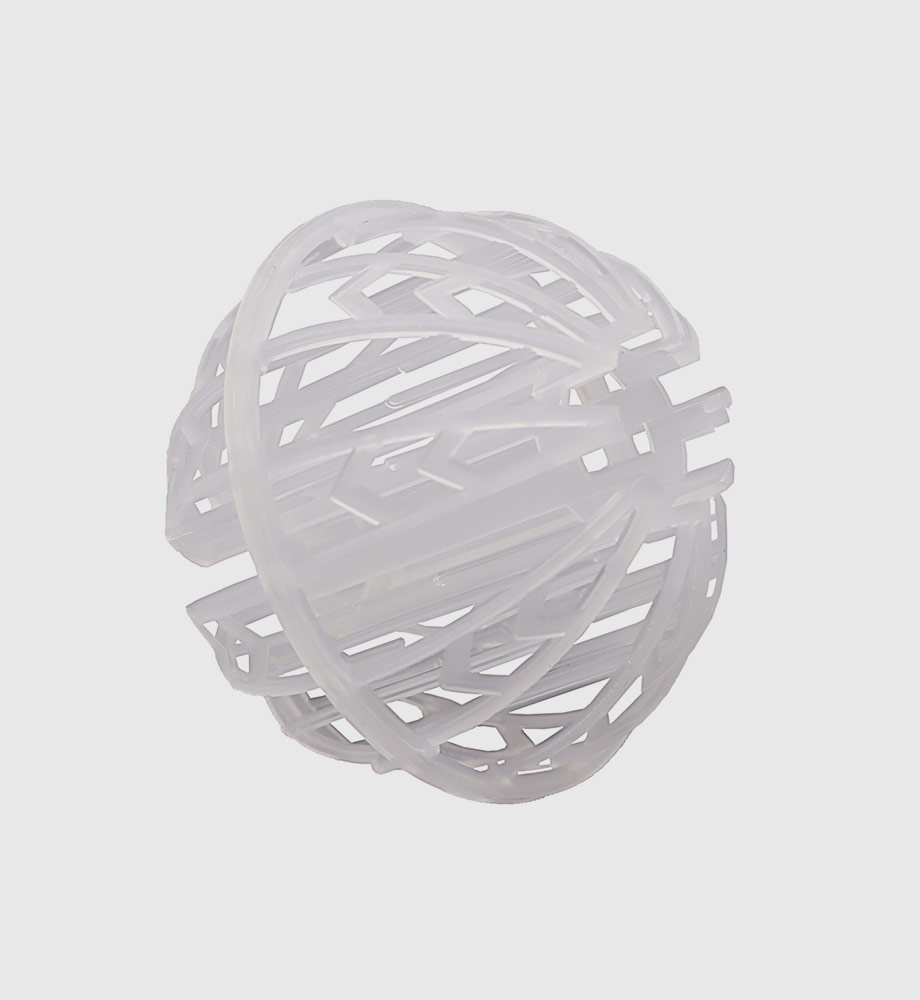

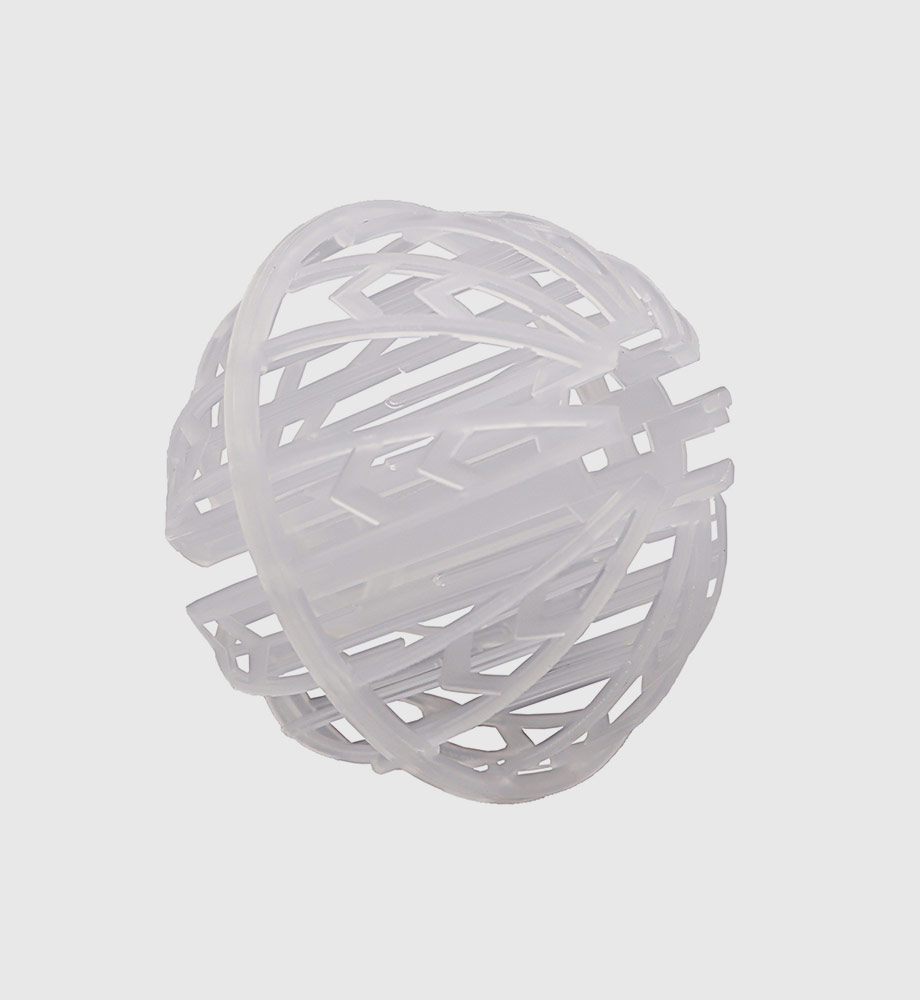

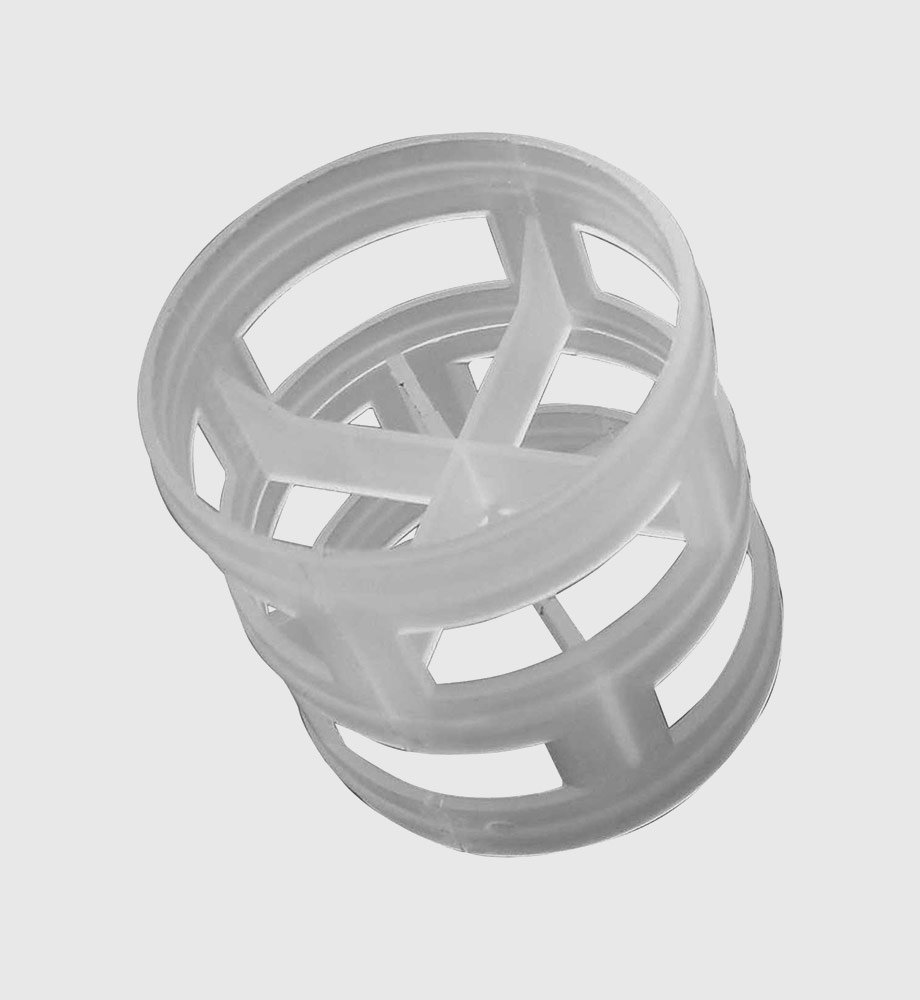

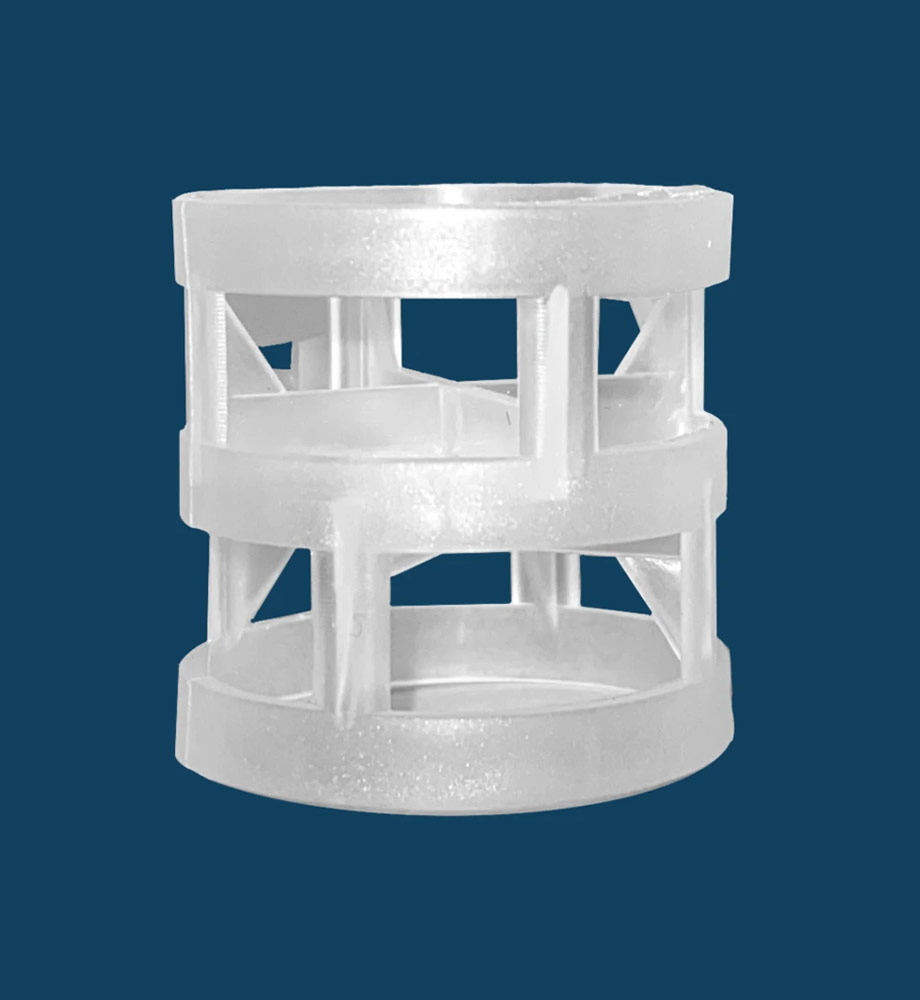

- High Surface Area: Many open channels and slots maximize surface for phase contact. For example, the classic Pall Ring’s slotted cylinder has high voidage and internal surface.

- Low Pressure Drop: Random packing shapes (rings, saddles) allow vapor to flow with minimal resistance.

- Chemical Options: Plastic packings (PP/PVC) for corrosive services; metal packings (stainless, Alloy) for high temperatures or pressure.

- Variety of Shapes: Includes Raschig rings, Pall rings, Saddles, Helix, etc., each with unique fluid-flow characteristics.

Benefits

- Efficient Separation: Enhanced contact leads to better mass transfer and purity in distillation/absorption.

- Flexibility: Packings can be added/removed to change column capacity or performance.

- Self-Cleaning: Many packings (e.g. Pall rings) have high liquid drainage, reducing fouling risk.

- Thermal Efficiency: Improves column performance without the power loss of high-pressure drop.

Applications

- Chemical Process Columns: Used in petrochemical distillation columns, acid gas removal, and ammonia synthesis towers.

- Water Treatment: Trickling filters and aeration towers use packed beds for gas exchange.

- Environmental Systems: Scrubbers for flue gases or contaminated emissions.

- Industrial Gas Purification: Towers for CO₂ scrubbing, NOx removal, etc.

Technical Specifications

- Materials: PP, PVC, PVDF, PP-GB (glass-filled) for plastics; stainless or alloy metals; ceramic.

- Dimensions: Vary by packing type – e.g. 20–100 mm diameter for rings.

- Voidage: Typically 80–95% open space (highly open structure).

- Surface Area: Often tens to hundreds of m²/m³ (packing factor) – for example, a Pall Ring might have ~130–200 m²/m³.

Unique Selling Points (USPs)

- High Mass-Transfer Performance: Pall Rings provide “inside surface access” with many contact points.

- Improved Gas-Liquid Contact: Advanced designs (e.g. Flower Pall Ring, S-series Saddles) offer even more transfer points and uniform liquid distribution.

- Corrosion Resistance: Plastic tower packings enable use in corrosive environments.

- Proprietary Designs: Some companies offer patented shapes (e.g. “Heilex”, “Cascade ring”) for specific process advantages.