Key Features

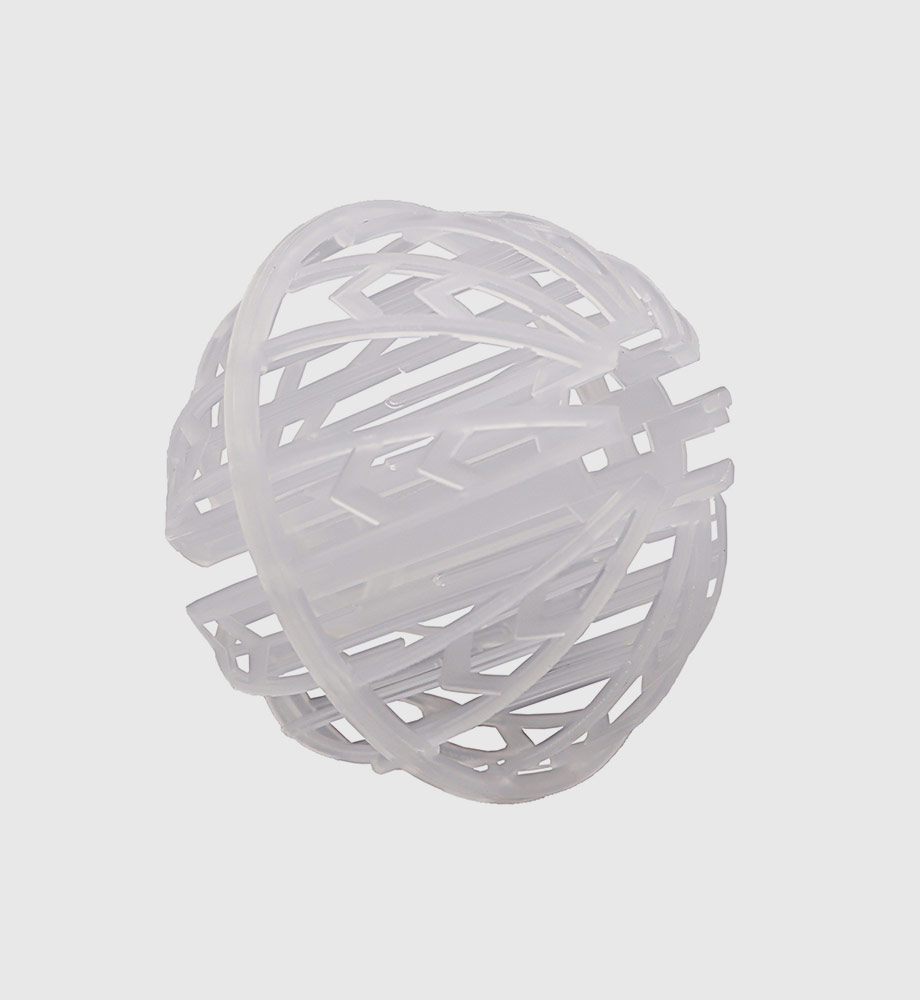

- Enhanced Geometry: Slotted walls with curved “petals” improve liquid distribution over the entire surface.

- High Surface Area: Even small sizes yield around 90–95 m²/m³.

- High Voidage: Typically very open (over 90% void fraction) to allow high throughput.

- Stable Packing Factor: Designed to self-lock and resist collapse, maintaining consistent performance.

Benefits

- Improved Efficiency: Better gas-liquid mixing than standard rings, leading to higher separation efficiency.

- Low Fouling: Open design resists clogging, ideal for dirty or viscous fluids.

- Ease of Handling: Lightweight plastic rings, easy to fill or dump from a column.

Applications

- Distillation Columns: Where maximum efficiency is needed at moderate pressures.

- Absorption Towers: Capturing contaminants or scrubbing gases with minimal resistance.

- Chemical Processing: Fractionation of specialty chemicals where fine separations are required.

Technical Specifications

- Materials: Commonly PP or PE (sometimes PVDF for high chemical resistance).

- Sizes: Standard diameter e.g. 1″, 2″, 3½″.

- Packing Factor: About 28 (dimensionless) for 1″ rings, dropping as size increases.

Unique Selling Points (USPs)

- Maximum Contact: Outperforms standard Pall Rings in efficiency due to complex surface shape.

- Versatility: Works in applications ranging from vacuum distillation to high-pressure absorption.