Key Features

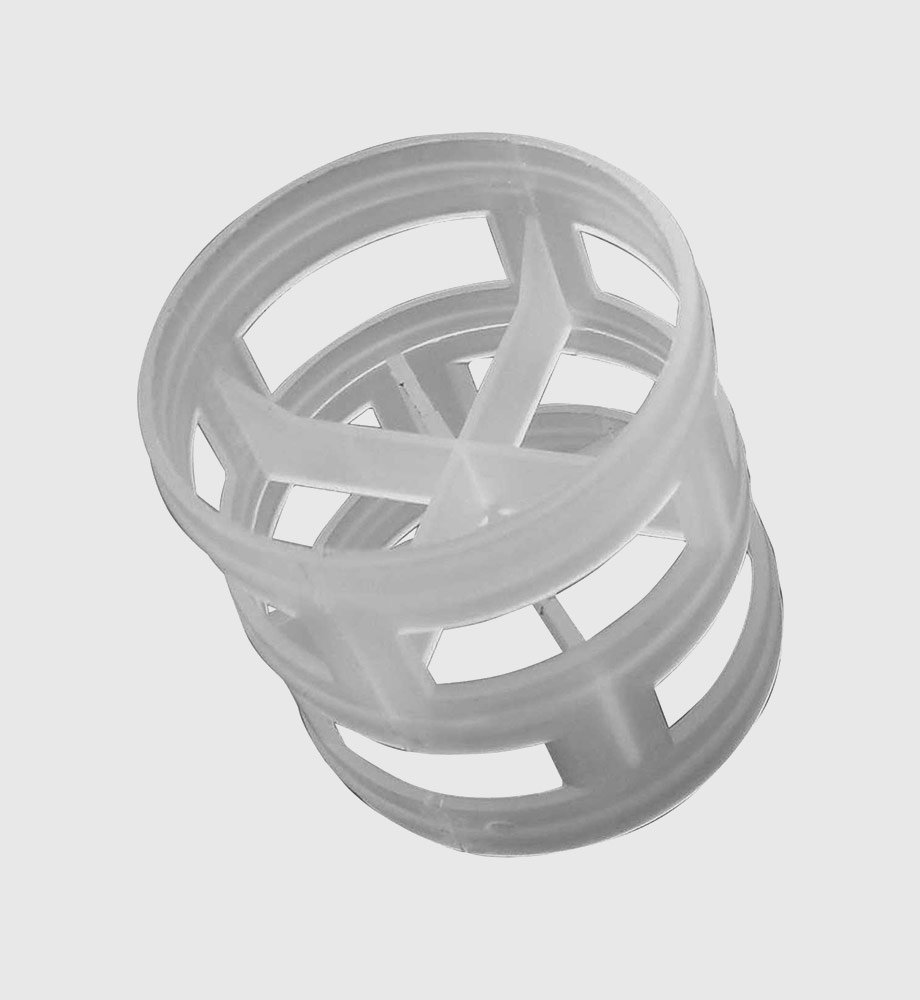

- Slotted Wall Construction: Each ring has several rectangular openings, allowing fluid to flow through the interior surface.

- High Voidage: Typically over 90% open space, ensuring low resistance to flow.

- Large Internal Surface: Inner surface access greatly increases transfer area.

- Multiple Materials: Available in PP, PVC, metal (IMTP rings), or ceramic.

Benefits

- Superior Mass Transfer: Efficient contact means fewer trays needed in a column.

- Robust Design: Strong and crush-resistant, with high fill ratio per column volume.

- Low Energy Use: Low pressure drop saves pumping energy.

Applications

- Petrochemical Distillation: Fractionators and rectifiers.

- Absorption Units: Gas scrubbers for H₂S, ammonia, CO₂ removal.

- Refinery Processes: Sulfur recovery, reforming.

Technical Specifications

- Surface Area: For example, a 50 mm OD Pall Ring has ~205 m²/m³ surface area.

- Voidage: Up to 92–97% depending on size.

- Packing Factor: A measure of packing efficiency; around 85–137 depending on diameter.

Unique Selling Points (USPs)

- Proven Performance: The original random packing introduced decades ago, with reliable data and global availability.

- Enhanced Variants: Newer versions (Pall Ring-1, Pall Ring-2) further tweak geometry for optimized flow.