Go Back

Chemical Process Equipment

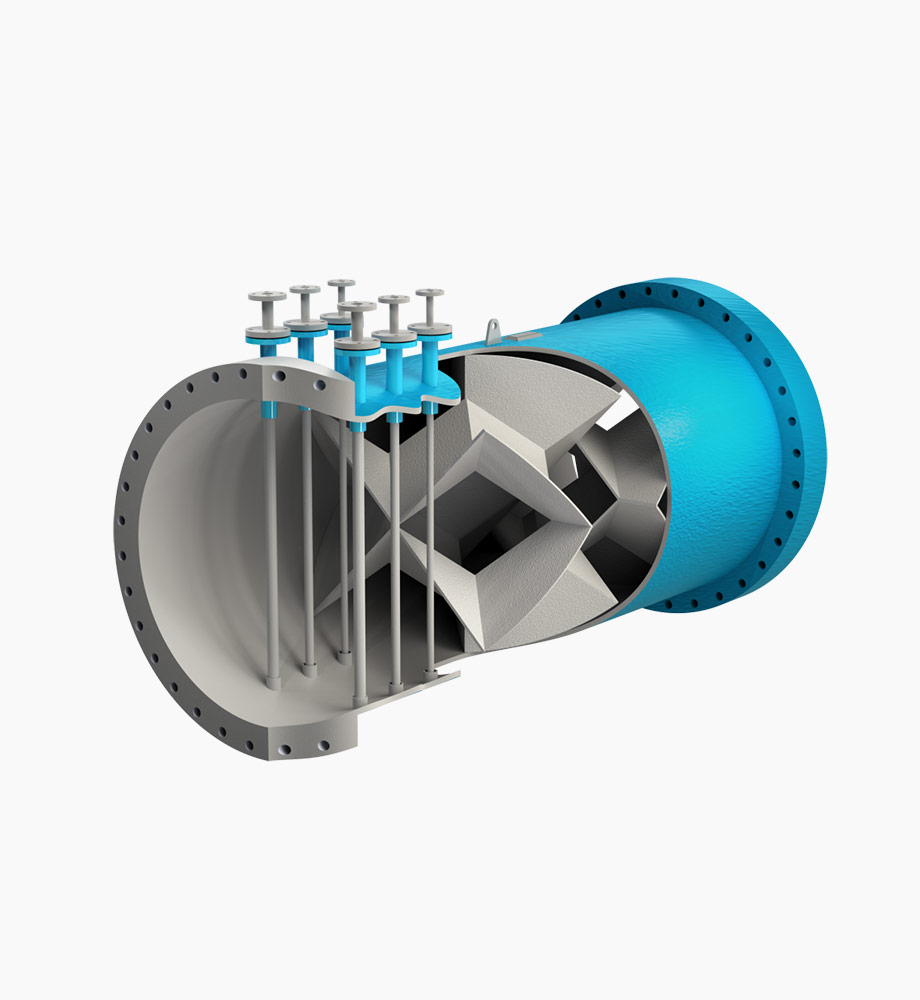

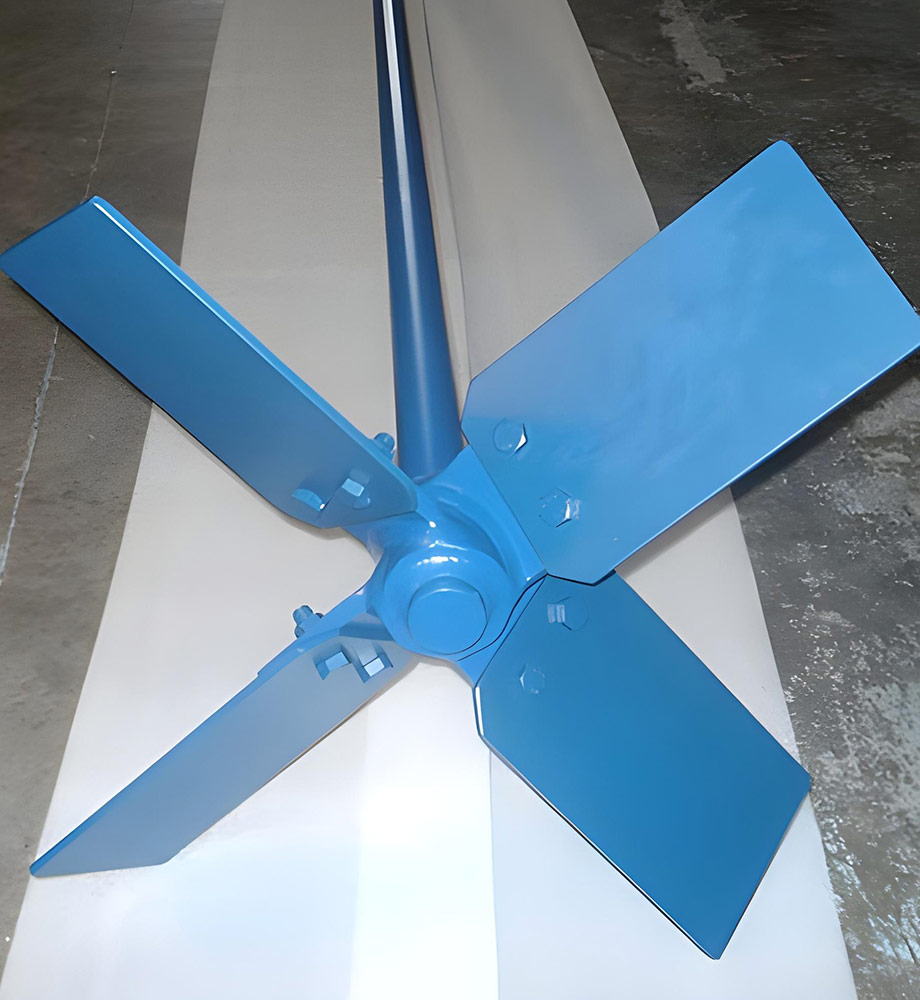

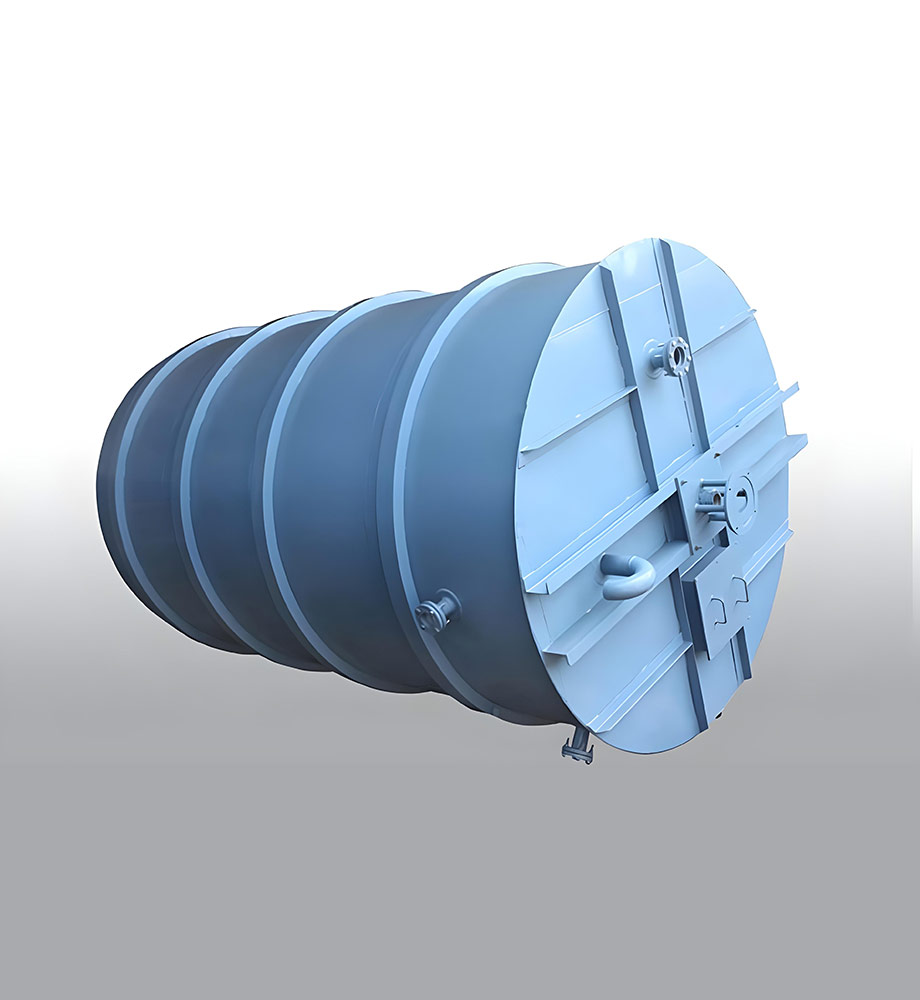

FRP chemical process equipment includes reactors, scrubbers, columns, and other vessels where chemical reactions or processing take place. These units are fabricated with seamless fiberglass construction and corrosion-resistant liners (PVC, PP, PVDF, PTFE, etc.). Designed per BS/ASTM/JIS/ASME/RTP standards, they safely handle corrosive fluids and can operate at pressures up to 10 bar. With features like UV and fire-retardant additives available, this equipment is suitable for highly aggressive chemical environments.

Product Inquiry

Key Features

Built to international design codes (e.g., BS 4994, ASME Section X, ASTM)

Constructed from FRP with premium thermoset resins (isophthalic/vinyl ester/epoxy) or dual FRP/thermoplastic liners

Capable of handling high temperatures (up to ~350 °C) and pressures (up to 10 bar)

Available in any shape (vertical/horizontal, with dished or flat ends) and designed for both vacuum and pressure service

Optional UV-stabilized, flame-retardant, and conductive (for static dissipation) additives

Benefits

Corrosion Resistance: Inert to acids, alkalis and solvents, preventing rust and corrosion for decades

Lightweight & Durable: FRP strength yields high mechanical and impact resistance while being easier to install than metal

Low Maintenance: Long service life (often 15–20+ years) with minimal upkeep and no need for frequent relining

Customizable: Tailored designs to fit plant layouts and process requirements, including special coatings and linings

Applications

Chemical & Petrochemical Plants: Reactors, mixers, separators for acids, bases, petrochemicals

Mining & Fertilizer: Corrosive leach tanks, ore processing vessels

Water/Wastewater: Acid/alkali neutralization, effluent treatment, scrubbers in water treatment

Power & Specialty: Desulfurization scrubbers (FGD), process towers in power/utility facilities

Technical Specifications

Design Standards: BS 4994, BS EN 13121, ASTM D3299, ASME RTP-1/X

Construction: Filament-wound or hand-laid FRP with interior liners

Liner Materials: PVC, CPVC, PP, PVDF, ECTFE, FEP, PFA

Pressure Rating: Up to 10 bar (g)

Temperature Rating: Typically up to 350 °C with appropriate liners

Materials of Construction: FRP using vinyl ester, epoxy, or polyester resins

Dual LAM Options: PP/FRP, PVC/FRP, PVDF/FRP, PTFE/FRP, etc.

Sizes/Capacities: 0.1–500+ m³ (100 L to 500,000 L)

Unique Selling Points (USPs)

Proven Heritage: Decades of experience (since the 1960s) in FRP chemical equipment manufacture

Safety Approvals: PESO-certified for petroleum storage tanks, CE marking available on pressure vessels

Field Support: Capable of on-site fabrication for very large equipment (e.g., >6 m diameter tanks)

Innovative Methods: Advanced winding techniques (Polar Winding) for efficient high-pressure vessel production

Chemical Process Equipment

SOCIAL MEDIA