Key Features

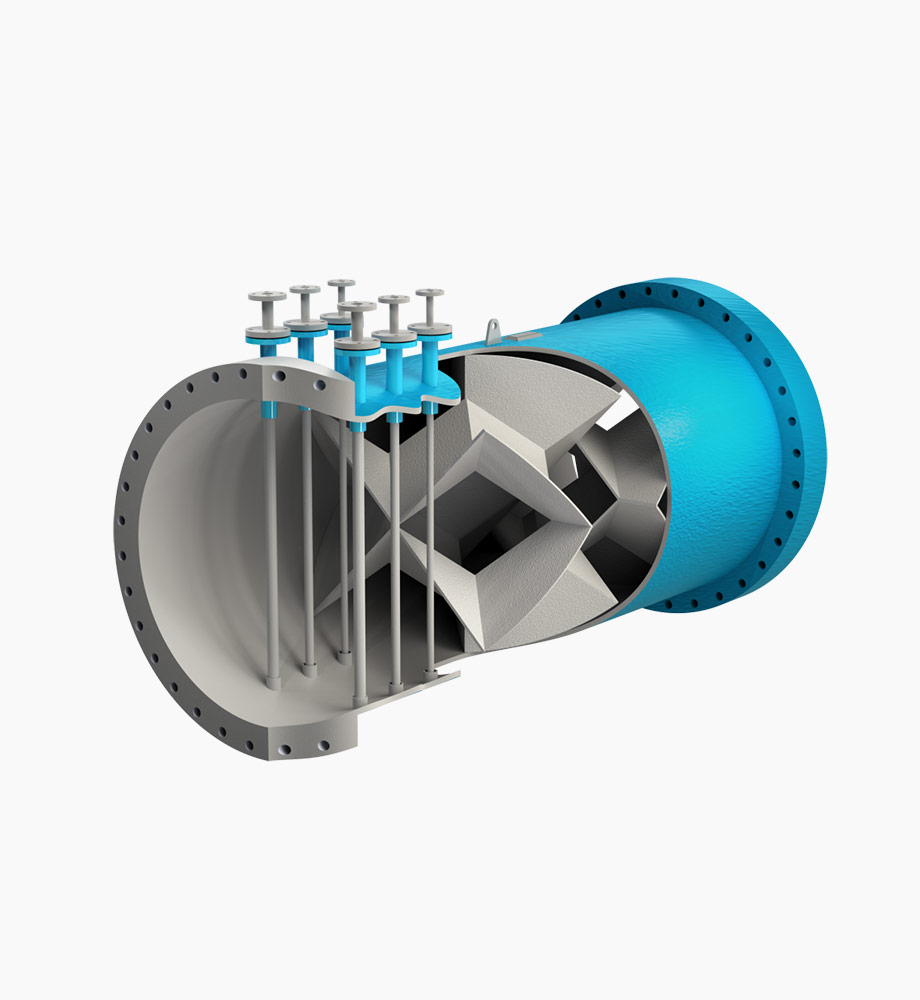

- Corrosion-Proof Components: FRP shafts and bearings eliminate corrosion issues common with metal agitators

- Variety of Impellers: Turbine, propeller, paddle, or anchor blades in FRP allow customization for specific mixing tasks

- Variable Speed Drives: Matching motor and gearbox configurations for different power requirements

- Splash-Resistant Sealing: Special seals (PTFE or ceramic) protect the drive mechanism from corrosive fluids

Benefits

- Chemical Compatibility: No contamination or deterioration when handling acids, alkalis, or solvents

- Reduced Maintenance: FRP parts do not rust or pit, extending equipment life

- Energy Efficient: FRP impellers are lighter, reducing energy consumption

Applications

- Chemical Processing: Agitation in reactors, neutralization tanks, electroplating baths

- Water/Wastewater: Mixing in clarifiers, neutralization, and equalization tanks

- Food & Pharma: Gentle, hygienic mixing solutions with FRP wetted parts

Technical Specifications

- Power Range: From fractional horsepower to tens of HP, depending on vessel size

- Speed: Adjustable, typically between 50 and 1500 RPM

- Materials: FRP resin (vinyl ester or epoxy) laminated blades; shafts made of SS316 or coated materials

- Mounting: Available in top-entry or side-entry configurations for closed tanks

Unique Selling Points

- Fully Engineered Mixers: Custom-designed to match process requirements (mixing time, shear, viscosity)

- Complete FRP Solution: Can supply both the mixer and matching FRP tank for seamless compatibility