Key Features

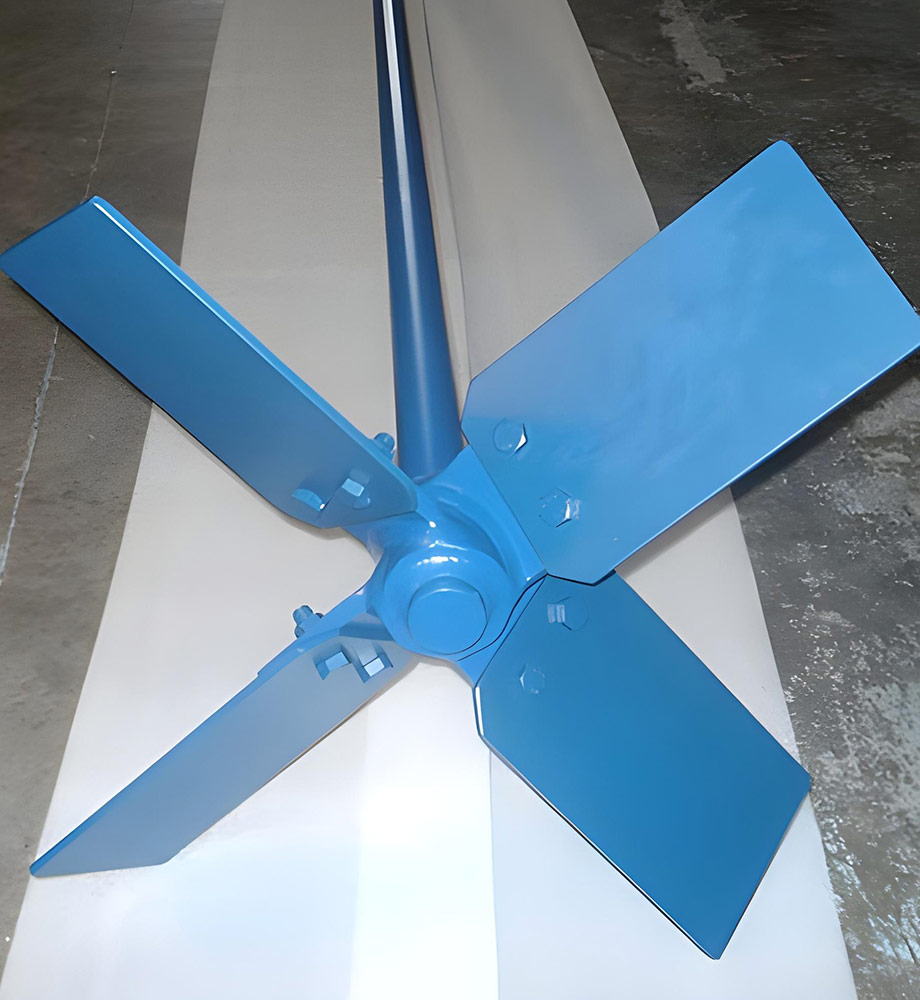

- Custom Shapes: Radial (propeller), axial (turbine), or angled blades to suit mixing needs

- Strong & Lightweight: Thick FRP construction yields high strength-to-weight ratio

- Blade Materials: Typically polyester or vinyl ester FRP; optional metal cores for extra stiffness

Benefits

- No Corrosion or Fouling: Surface remains smooth and clean, ensuring consistent performance

- Easy Installation: Light weight simplifies blade replacement and service

Applications

- As Replacements: For existing mixers in chemical or wastewater plants

- New Equipment: Supplied with new FRP mixers or retrofitting processes

Technical Specifications

- Diameter: Ranges from 100 mm to 2000 mm, tailored to vessel size

- Thickness: Typically between 5 mm and 20 mm, depending on size and design

- Materials: Made from isophthalic/polyester or vinyl ester FRP

- Balance: Dynamically balanced to minimize vibration

Unique Selling Points

- In-House Design: Blades designed for optimal hydrodynamics in specific mixing applications

- Abrasion Resistant Options: High abrasion epoxy liners available for slurry mixing