Key Features

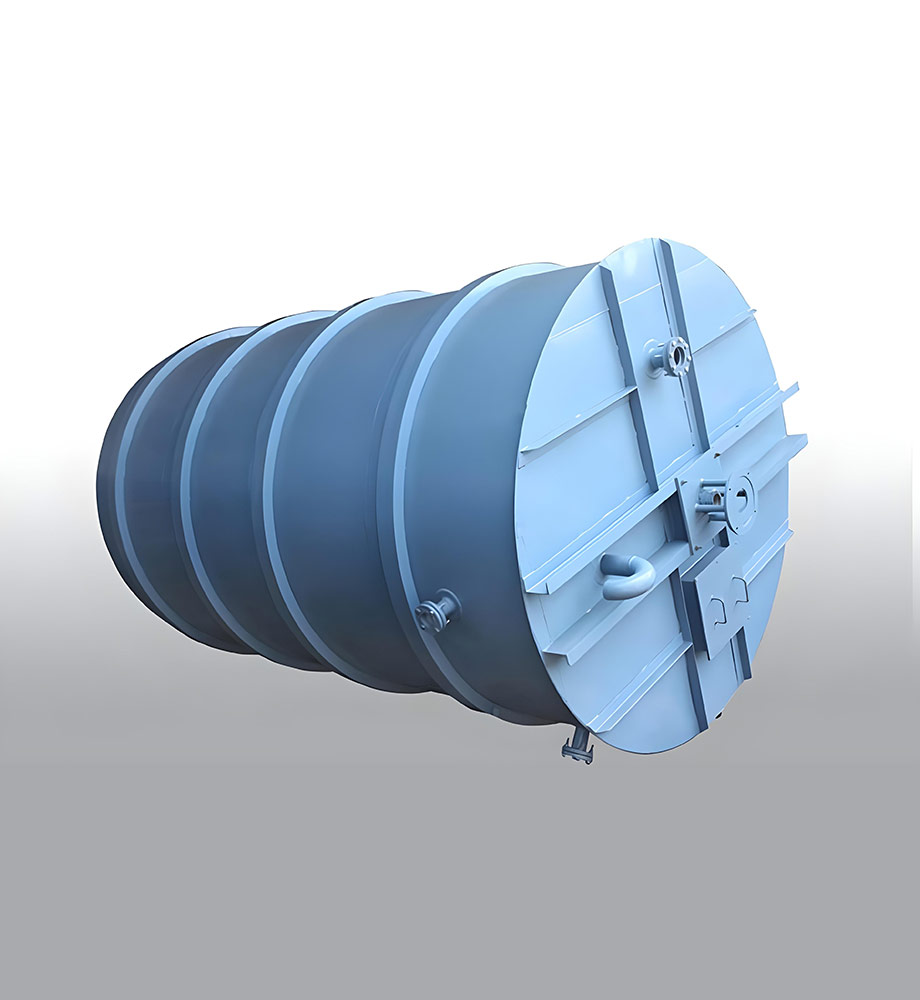

- Agitated or Draft-Tube Design: FRP mixers create uniform supersaturation.

- Temperature Control: Jackets or coils for cooling integration.

- Overflow/Discharge: Sloped bottom or centrifuge discharge configurations.

Benefits

- Corrosion Inert: Handles acid salts and alkali salts equally well.

- Ease of Cleaning: Non-stick FRP makes cleaning out crystals simpler.

Applications

- Chemical Industry: Crystallization of fertilizers, inorganic salts, sulfonates.

- Waste Recovery: Salt recovery from brine streams.

Technical Specifications

- Batch Volume: Customizable, typically between 500 to 5000 L.

- Construction: FRP with thick laminate; corrosion-proof outlet.

- Temperature Range: From ambient temperature up to approximately 80 °C.

Unique Selling Points

- Complete Project Supply: Can include FRP dryer or filter vessels for downstream processing.