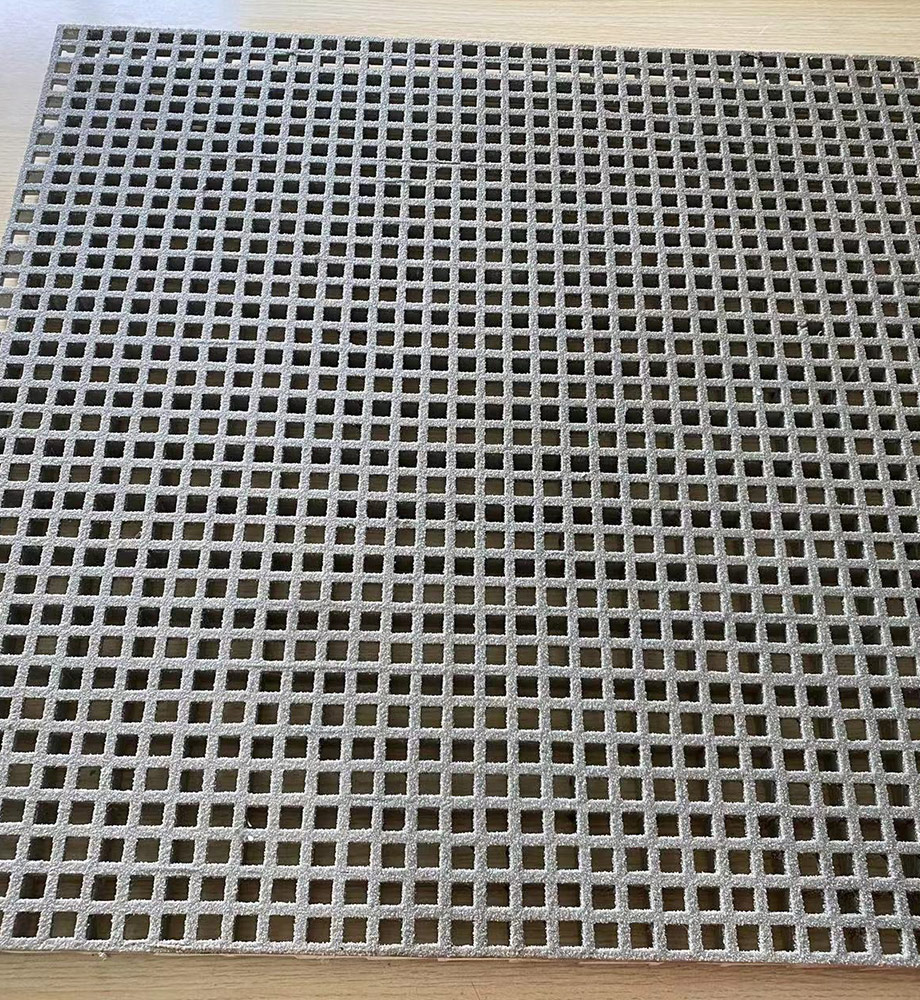

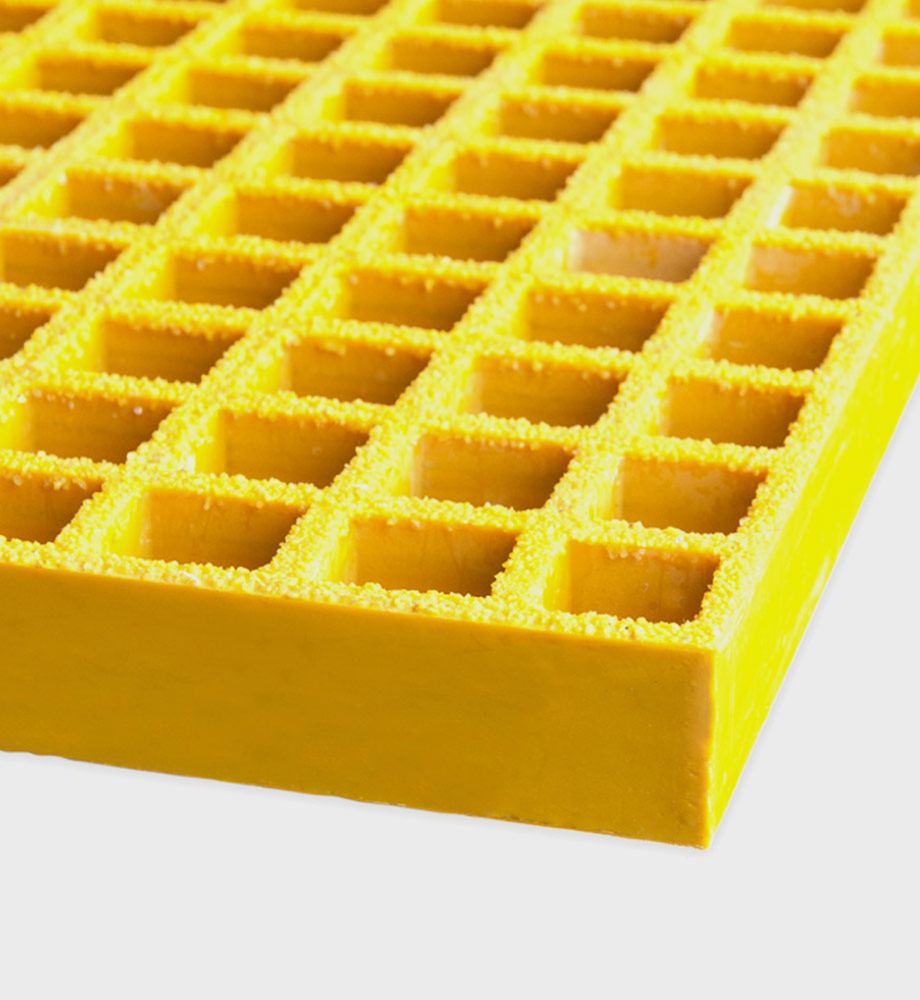

Moulded Gratings

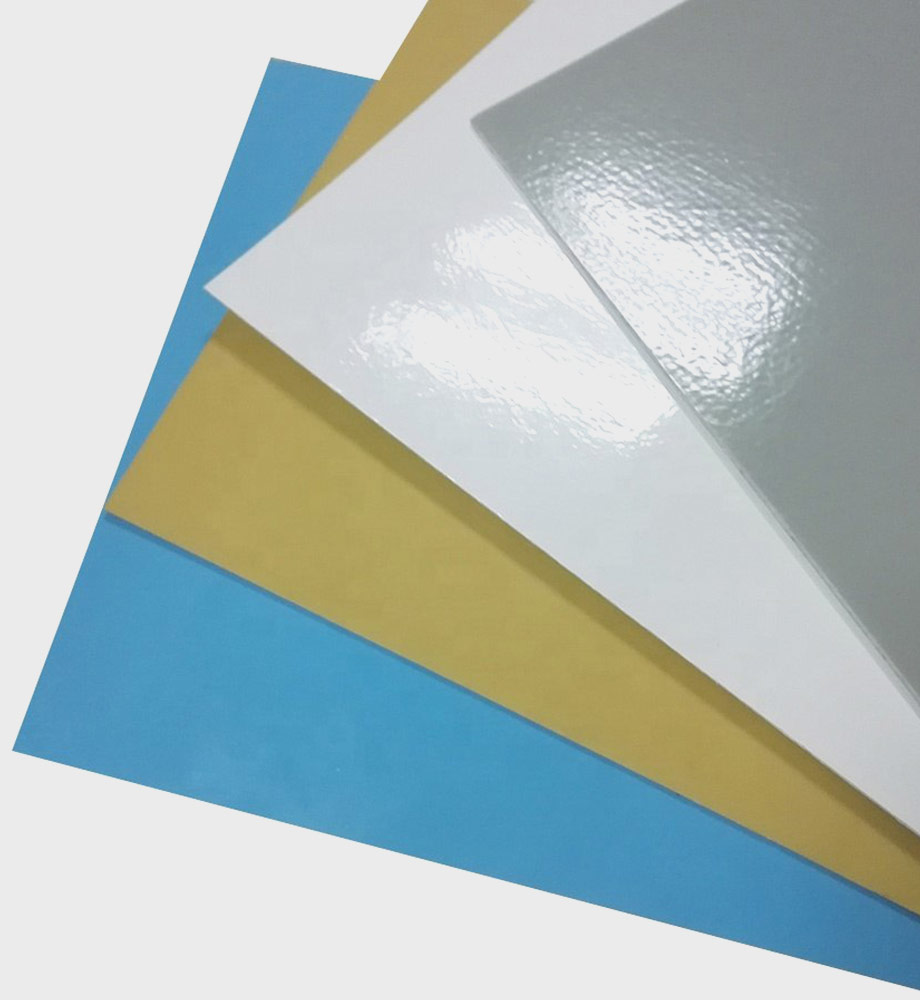

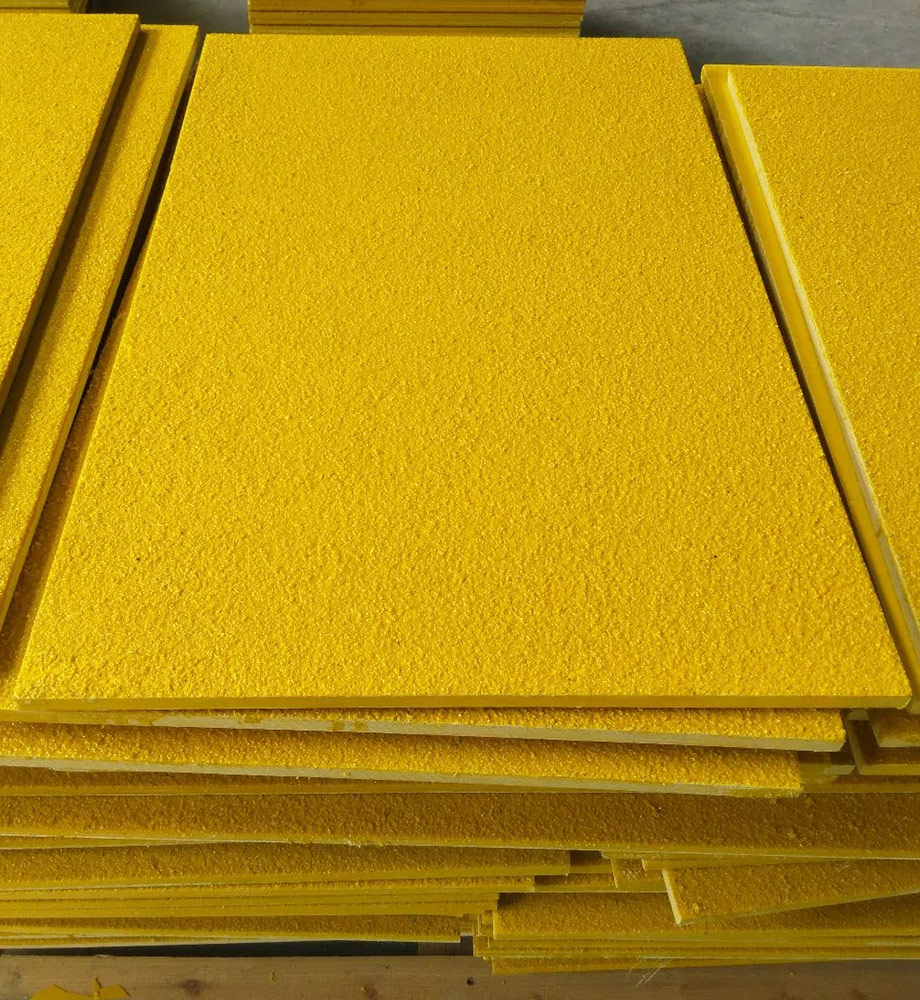

Moulded FRP gratings are manufactured by casting glass fibers and resin in a mold to form a single-piece panel. This yields bi-directional strength (equal in X and Y directions) and a smooth, uniform appearance. These panels inherently come in a square/rectangular mesh pattern and can be produced with several surface textures. During molding, the mixture of continuous fiberglass rovings and high resin (typically ~65% by volume) creates very chemical- and corrosion-resistant panels. As a result, moulded grating is often chosen for highly caustic or wet environments where safety is paramount.

Moulded FRP gratings (as above) offer exceptional load-carrying capacity in all directions. Their manufacturing process yields high uniformity and durability: panels won’t delaminate or rust, and they resist UV and fire (standard panels meet ASTM E84 Class 1). Custom panels can include fire-retardant or anti-static resins. All panels can be drilled or cut on site with standard tools.

Product Inquiry