Key Features

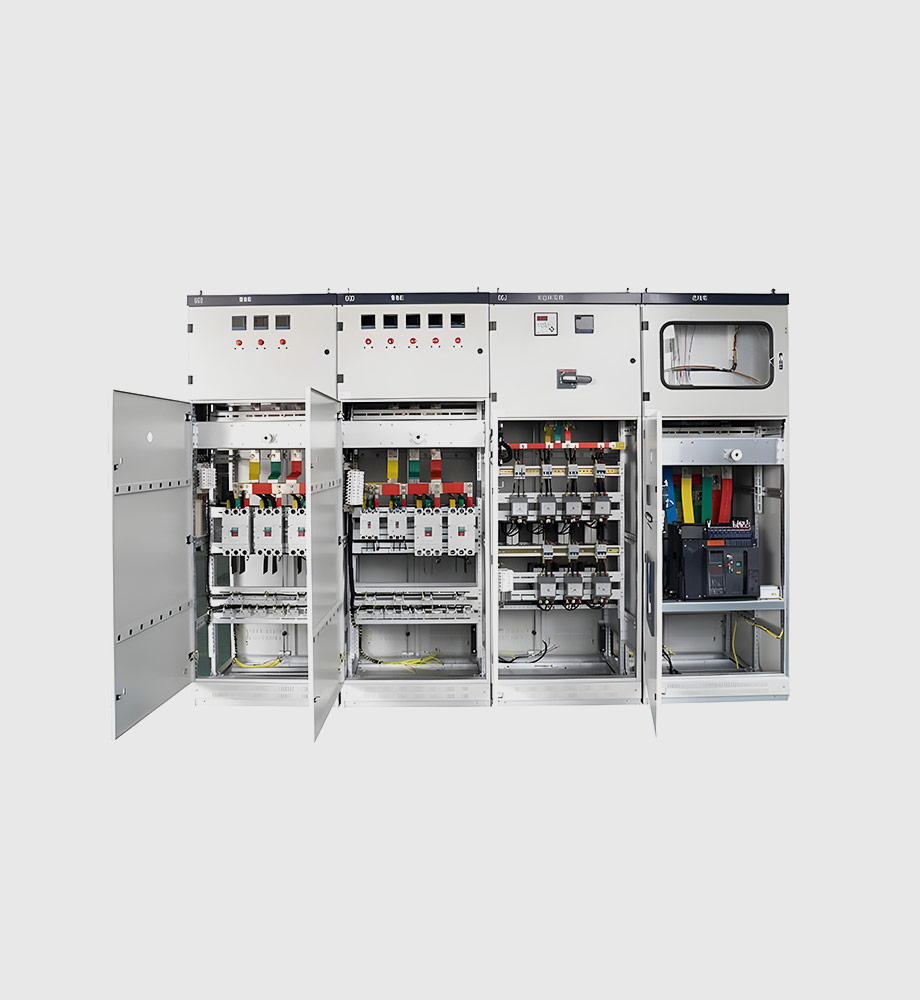

- Insulating Panels: When non-metallic, made of high-strength thermoset or thermoplastic materials (similar to circuit breaker cases).

- Arc-Flash Containment: Engineered to contain arcs and direct hot gases safely.

- Sealing: Often rated for indoor IP54–IP65, or outdoor NEMA 3R–4X, to protect against dust and rain.

- Mounting Infrastructure: Pre-cut openings and mounting provisions for breakers, meters, and control devices.

Benefits

- Enhanced Safety: Insulated enclosures eliminate risk of electrical conduction through the housing.

- Environment Protection: Keep out water and contaminants, prolonging equipment life.

- Modular Assembly: Sections can be combined to build large gear setups (e.g. MCC cubicles).

Applications

- Medium/Low Voltage Panels: Control and distribution panels in factories, substations, and buildings.

- Hazardous Areas: Explosion-proof or dust-tight housings for volatile industrial settings (often metal, but insulated variants exist).

- Outdoor Substations: Fully sealed switchgear for outdoor power distribution.

Technical Specifications

- Material: Often glass-fiber polyester or flame-retardant plastic.

- Protection Level: Commonly IP54/55 indoors; IP66/IP67 for outdoor rated gear.

- Standards: IEC 62271 (high voltage switchgear), UL 891 (switchboards).

Unique Selling Points (USPs)

- Robust Insulation: Similar materials as MCCB casings ensure high dielectric strength.

- Customization: Can be engineered with viewing windows, interlocks and ventilation as needed for complex power systems.