Key Features

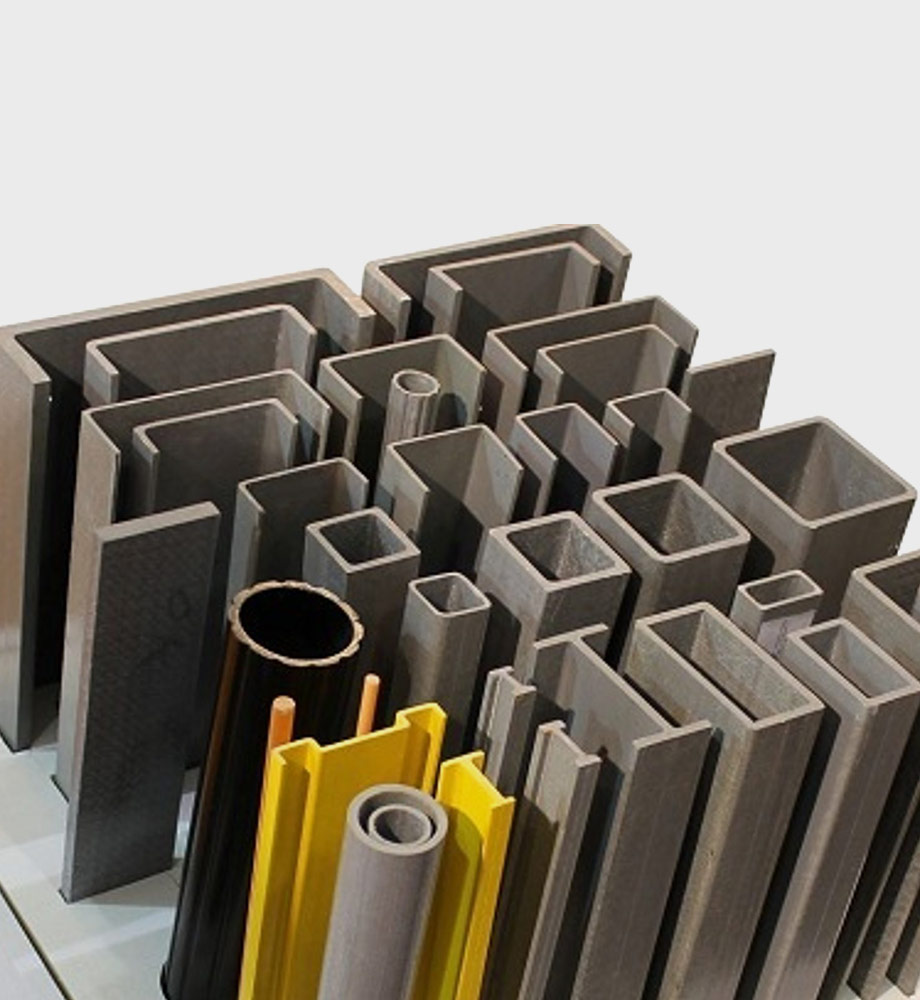

- Available in many shapes and sizes (U-channel, I-beam, square/rectangular tube, flat bar, L-angle, etc.). High tensile and flexural strength (often matching or exceeding that of mild steel), with low weight (typically 25–35% of steel). Made of fiberglass/polyester or vinyl ester resin for UV, chemical, and corrosion resistance. Non-conductive and non-magnetic.

Benefits

- Long-lasting support structure that will not corrode or pit in wet, chlorinated environments. Low maintenance – no repainting or galvanizing needed. Easy handling and installation due to light weight, which reduces labor and equipment costs. Excellent fire performance with appropriate resins. Provides significant lifecycle cost savings over steel or wood.

Applications

- Main load-bearing framework and structural members of cooling towers: support beams, columns, catwalks, ladders, handrails, and equipment mounts. Also used for grating supports and platforms around the tower basin. FRP profiles are chosen where traditional materials (steel or wood) would rapidly degrade (e.g., at splash zones and hot water basins).

Technical Specifications

- Typical pultruded profiles have fiber content 60–75% by weight, with tensile strengths often in the range of 200–400 MPa and flexural moduli 10–20 GPa. Standard lengths are 6–12 m (custom lengths available). Section sizes vary by manufacturer – for example, a 150x50mm FRP channel can carry loads similar to a comparable steel channel.

Unique Selling Points (USPs)

- Corrosion immunity in the most aggressive cooling tower environments. Comparable load capacity to steel at a fraction of the weight; one manufacturer notes FRP is “sturdy as steel” yet much lighter. In addition, FRP profiles will not rot (like wood) or corrode (like steel), and they help prevent galvanic corrosion issues. FRP’s long-term dimensional stability improves safety and reduces downtime over the life of the tower.