Key Features

- High strength-to-weight ratio (comparable strength to steel)

- Excellent corrosion resistance (immaterial to rust or acids)

- Light weight (pultruded composite is ~75% lighter than steel)

- Non-conductive & non-magnetic (electrical insulation)

- Flame- and UV-resistant (long-term outdoor durability)

Benefits

- Long service life with minimal maintenance (no painting or replacement)

- Instant corrosion immunity in chemically aggressive or coastal environments

- Thermal and electrical insulation (suitable near electrified areas)

- Savings on handling/shipping due to lightness; easy to install on-site

- No corrosion fatigue – maintains mechanical properties over decades

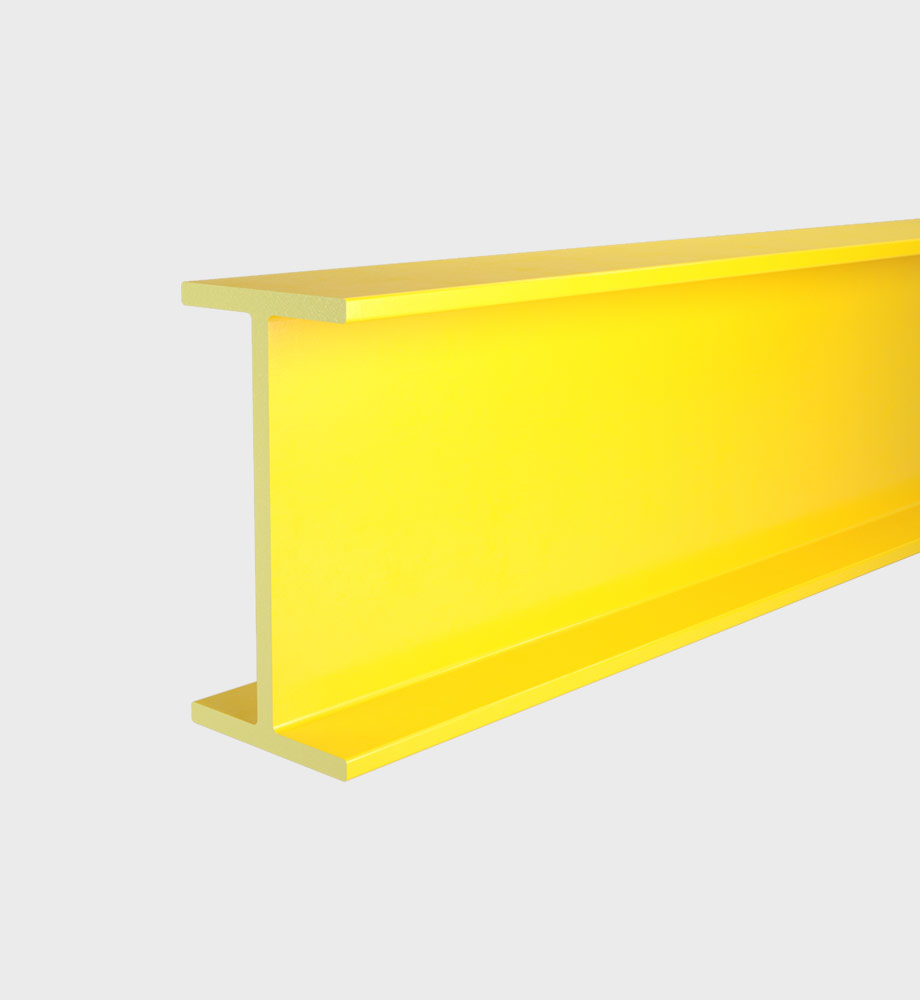

Applications

- Structural beams and columns in industrial buildings, platforms, walkways, bridges

- Support beams for elevated platforms, stairs and catwalks (including refrigerated truck floors)

- Bridge and girder components (especially in marine or de-icing environments)

- Chemical plants, coastal docks, wastewater treatment where steel beams would corrode

- Reinforcements in cooling towers, utility racks, pipeline supports

Technical Specifications

- Sizes/sections pultruded by meter (e.g. 50x102x6.4 mm etc. [kg/m listed])

- Meets EN 13706, ASTM D4385 or equivalent standards (CTI 137 for glass fibers)

- Density ~1.8 g/cm³ (typical of FRP profiles) with tensile moduli often 15–20 GPa

- Available in polyester, vinylester or isophthalic resins, with optional fire-retardant additives

Unique Selling Points (USPs)

- Non-corrosive & non-rotating (ideal for lifetime service in marine and chemical environments)

- Extremely lightweight relative to strength (reduces foundation load and transport cost)

- Low thermal conductivity (better insulation than steel)

- Broad customization: any flange width/height and web thickness can be pultruded on demand

- Long warranties & proven performance (used for 40+ years in critical infrastructure)