Key Features

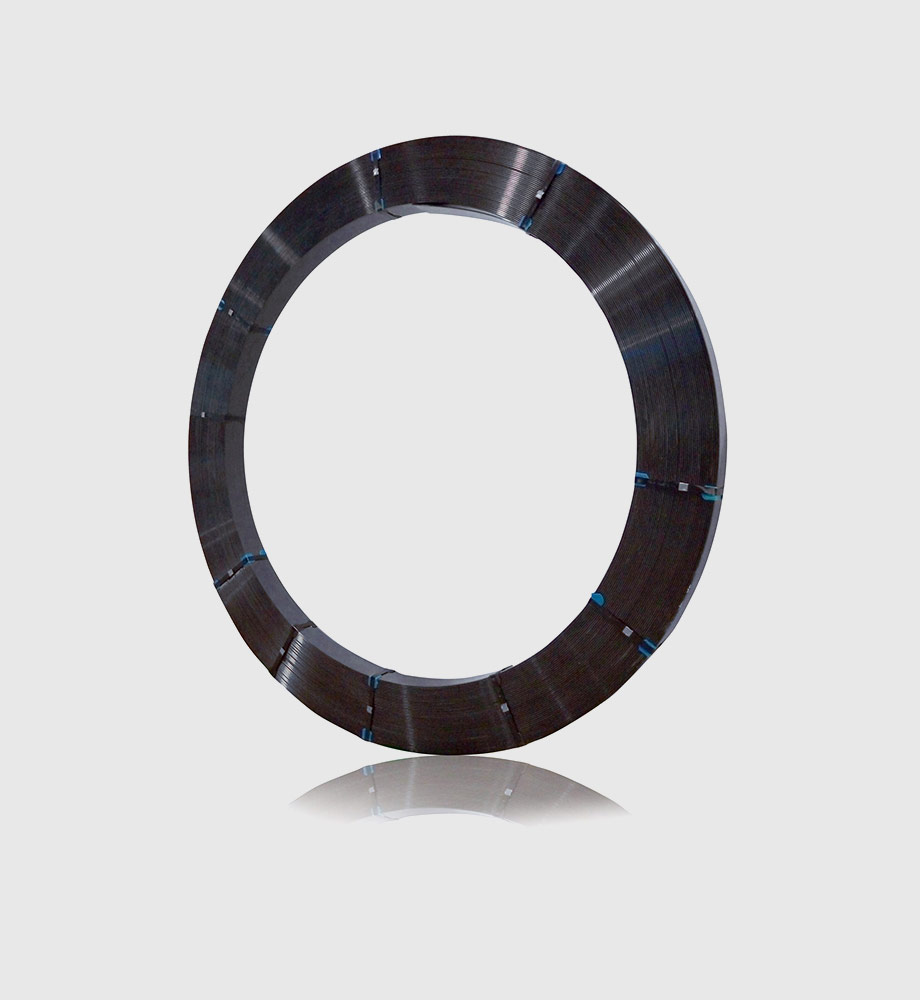

- Unidirectional fibers aligned with the blade span; high fiber volume fraction (>60%); epoxy or vinylester matrix for toughness; cut-to-length precision.

Benefits

- Provide enormous bending stiffness and strength, allowing the blade to support heavy aerodynamic loads. Sparcaps enable weight reduction by allowing thinner skins. They are the key to scaling blades to longer lengths.

Applications

- Integral to all composite blade designs. Used at blade root and sometimes extended towards tip depending on load profile. Also used in other composite structures needing high bending capacity (e.g. mast sections).

Technical Specifications

- Sparcap laminates can be up to 20 cm wide near the root (for multi-MW blades) and taper along the span. Typical materials include high-modulus carbon fiber (240–400 GPa modulus) or E-glass (70–80 GPa). Adhesive bond lines and insert laminates meet ASTM adhesion strength >15 MPa.

Unique Selling Points (USPs)

- Our sparcaps are produced using high-precision pultrusion and laser cutting. We offer both glass and carbon options, with certification data ensuring fatigue life per IEC standards. Advanced quality control (C-scan, ultrasonic) ensures defect-free, high-performance parts.

- PU (Polyurethane) Components

- Epoxy

PU (Polyurethane) Components

The PU product line comprises high-performance polyurethane materials used in wind energy manufacturing and maintenance. This includes 2-component structural adhesives and foam core materials. PU adhesives (polyurethane resins) are often used for bonding blade skins, cores and add-on parts. Rigid PU foams are used as lightweight core filler (e.g. blade core, nacelle insulation). Our PU systems are formulated for tough, elastic bonds and foams with uniform cell structure.

Key Features

- Structural PU Adhesives: 2K polyurethane adhesives (like SikaForce series) offer high elasticity and crack resistance. They cure at room temperature, have excellent gap-filling and wet-out, and come in fast- or slow-curing options.

- PU Foam Cores: Closed-cell rigid polyurethane foams (typically 100–250 kg/m³) with high compressive strength. Available in block or block-cut panels, or pour-in-place mix.

- Sealants and Fillers: PU-based fillers (pasty putties) for aerodynamic profile finishing.

Benefits

- Tough Bonds: PU adhesives provide flexible, fatigue-resistant joints that absorb stress without cracking. They are ideal for sandwich panels and bonding dissimilar materials.

- Lightweight Cores: PU foam cores drastically reduce weight while maintaining rigidity, improving blade and nacelle performance.

- Fast Processing: Many PU systems cure rapidly and allow easy pumping/mixing. Long open time formulas enable large layups, while fast-cure options speed up assembly.

Applications

- Structural bonding in blade and nacelle assembly (blade-to-hub joints, core lamination, etc.); vibration-damping mounts; encapsulation of electronics. PU foams are used inside blades (core filler), as thermal/acoustic insulation in nacelles, and as mold release stoppers.

Technical Specifications

- Adhesives are two-part (A:B) mixed typically 1:1 to 10:1 by weight, with viscosities ranging ~500–5000 cP. Shore hardness after cure varies from ~70 to 90A. Foam densities and expansion rates are chosen per application. Products meet relevant ISO/IEC standards for tensile/shear strength (often >20 MPa shear), and many systems hold certifications like DNV or UL for use in offshore environments.

Unique Selling Points (USPs)

- Our PU components are sourced from industry leaders (e.g. Sika, Huntsman) and formulated for wind applications. We provide global supply chains ensuring consistent quality. Compared to epoxy adhesives, PU systems deliver tougher, more impact-resistant joints. Our technical support can help select the optimal PU chemistry for each design

Epoxy

Epoxy products include resins and adhesives crucial for turbine manufacture. Epoxy laminating resins are used in blade, nacelle and tower composite laminates, providing high mechanical strength and thermal stability. Epoxy adhesives (2-component) are the industry standard for structural bonding of wind components. They cure to a rigid finish with excellent environmental resistance. For example, Sika’s blade bonding epoxies offer “excellent strength and crack resistance” for blade assemblies. We supply a range of epoxies for infusion, prepregs, fixture bonding, and repair.

Key Features

- Structural Resin: 2K epoxy laminating resin systems (infusion or spray) with low viscosity for complete fiber wet-out.

- Bonding Adhesives: Epoxy adhesives (often rigid toughened) for blade-to-hub, shell-to-structure bonds. Many are pre-filled (paste) for gap-filling.

- Repair Compounds: Fast-curing epoxy fillers for patching defects and finishing surfaces.

Benefits

- High Strength & Stiffness: Epoxies cure to a strong, dimensionally stable matrix, superior to polyester for fatigue performance.

- Excellent Adhesion: Bonds strongly to composites, metals and concrete; prevents adhesive failure under load.

- Chemical Resistance: Withstands fuels, oils and temperature cycles, important inside nacelles.

- Versatility: Wide range of formulations (fast-curing, heat-curing, low exotherm) to suit different process needs.

Applications

- Widely used in wind blade infusions (resin systems like SikaBiresin®) and in high-performance adhesives (SikaPower® series) for bonding blade laminates, hatches, and structural joints. Also used for mold repairs, plug manufacturing, and tower component fabrication.

Technical Specifications

- Epoxy adhesives come in 2K cartridges or drums, with mix ratios typically 100:30 by weight (A:B). Typical cured properties include tensile strengths >50 MPa and Tg up to 80–120°C (depending on grade). Class II and III laminating resins meet DIN 16878-2. Adhesives often meet UL94 V-0 after cure.

Unique Selling Points (USPs)

- We offer epoxy products tuned to wind industry demands. For example, SikaPower-830 is a globally validated blade adhesive with consistent quality worldwide. Our epoxies can be sourced regionally to reduce lead time. We also provide technical datasheets and on-site support to optimize cure schedules and ensure compliance with turbine OEM standards.