Key Features

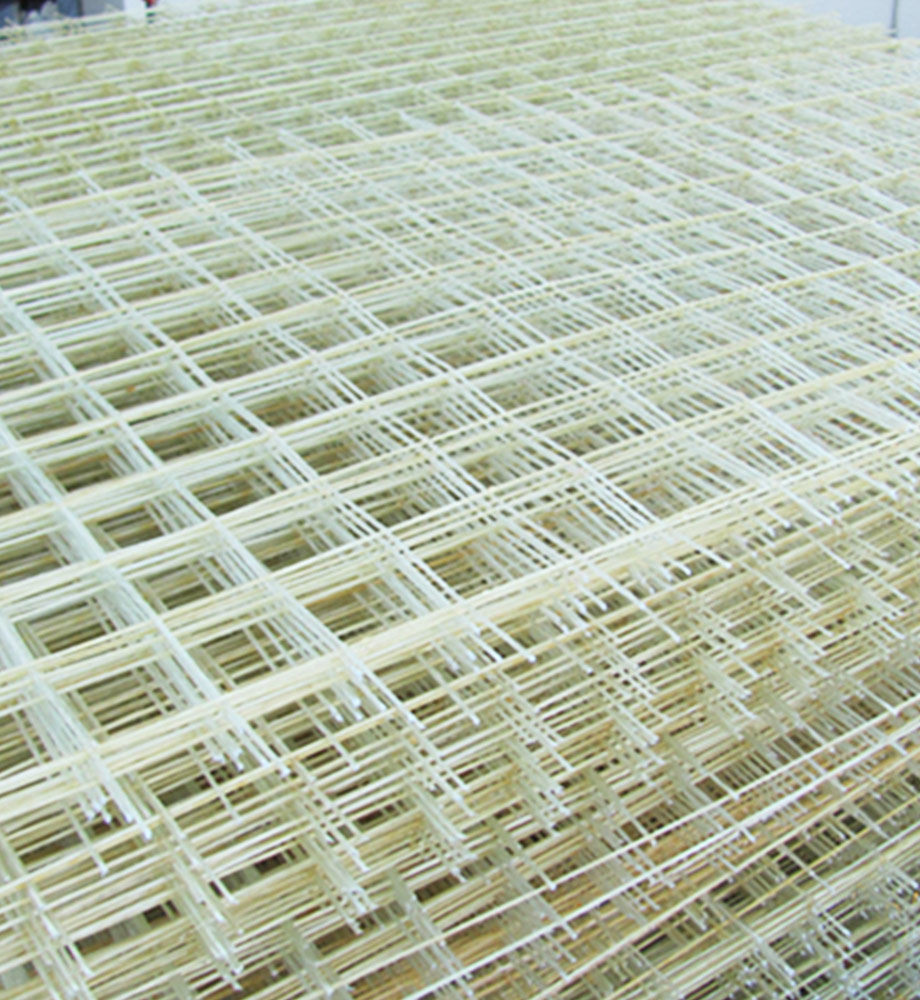

- Pre-fabricated glass fiber grid (commonly 25×25mm or 50×50mm grid sizes); extremely corrosion-resistant matrix; high tensile strength (up to 3× that of steel mesh); lightweight (typically ~1/9th the weight of equivalent steel mesh); non-conductive, non-magnetic.

Benefits

- Extends pavement and slab life by preventing steel corrosion failures. Easier to handle and cut than steel mesh (saving labor time). Improves fatigue resistance and crack control in concrete, even under extreme temperatures or chemical exposure. Reduces whole-life maintenance costs due to durable mesh performance.

Applications

- Reinforcement of concrete road overlays, bridge decks, airport runways, tunnel linings, industrial flooring, parking structures, and waterfront or marine concrete works. Particularly suited for projects exposed to deicing salts, aggressive groundwater, or high-humidity environments.

Technical Specifications

- Common mesh styles include welded grids of 2.5–6 mm diameter GFRP rods spaced 50–200 mm apart. Typical tensile strength is ~1,000–1,300 MPa, with low elastic modulus (around 55–60 GPa) and thermal expansion similar to concrete. Mesh is usually available in rolls or panels up to several square meters.

Unique Selling Points (USPs)

- 100% non-corrosive mesh that will “never rust,” providing lifetime reliability. Significantly lighter and easier to install than steel mesh, with reduced need for on-site cutting. Its superior bond to concrete minimizes crack width. Using FRP mesh also reduces scrap and waste from cutting steel, contributing to sustainability.