Key Features

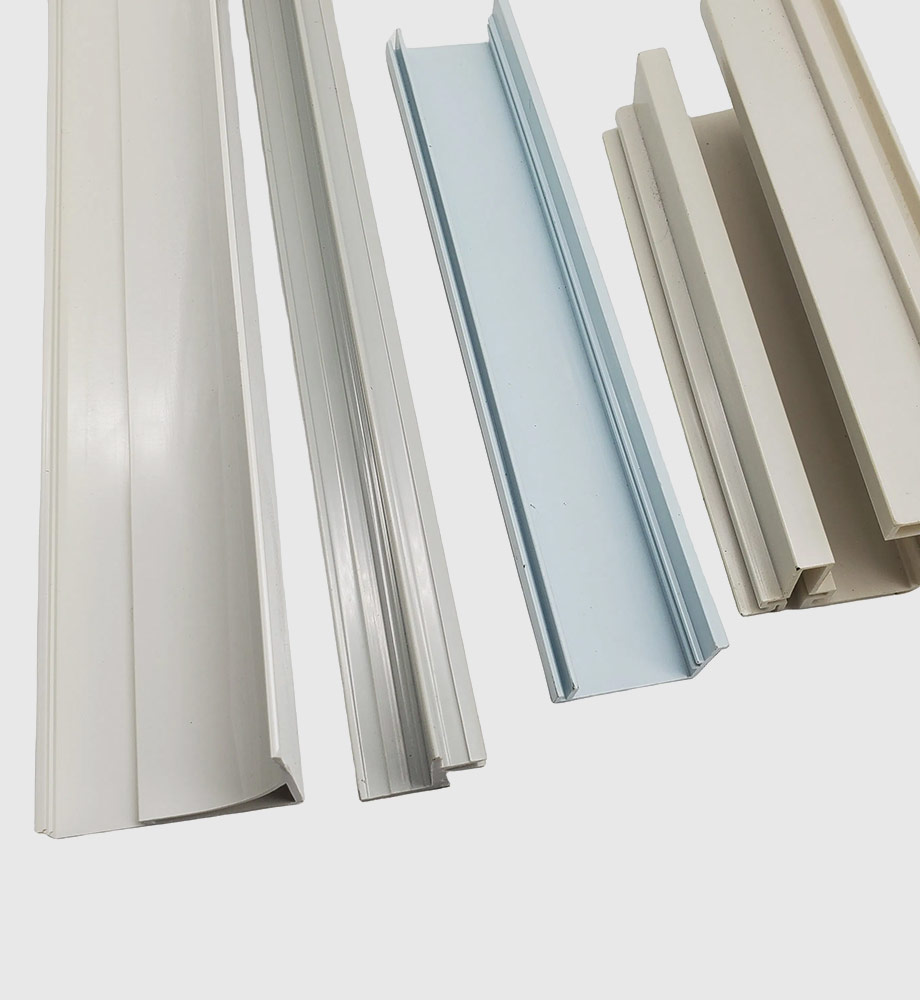

- Material Flexibility:

- PVC Frames: Provide rigidity and fire retardance; often UL94 V0.

- Polypropylene Frames: Chemically inert to acids/alkalies (ideal for filter frames in labs).

- Nylon Frames: High impact strength and thermal stability for demanding uses.

- Molded Precision: Tight tolerances and smooth finishes, suitable for sealing applications.

- Corrosion-Resistant: All plastic frames resist rust or rot in damp or outdoor use.

- Custom Designs: Can be molded to fit standard filter sizes or custom panel dimensions.

Benefits

- Maintenance-Free: No painting or galvanizing needed; withstands weather without cracking.

- Dimensionally Stable: Plastics do not warp under moisture like wood.

- Lightweight: Easier to handle and mount than metal frames of the same strength.

- Aesthetic Finish: Clean, consistent look – plastic can be colored or textured.

Applications

- HVAC Filter Frames: Holding filter media in air handling units or ventilation grills.

- Electrical Enclosure Fronts: Frame the mounting aperture for displays or modules.

- Equipment Racks: Panel frames for mounting controls or connectors in machine frames.

- Signage and Displays: Outlining digital screens or optical filters in devices.

Technical Specifications

- Material Grades: Often injection-molded PVC (rigid), PP (impact copolymer), or Nylon (PA6/6 GF30).

- Fire Rating: Many use UL94-rated resins for flame suppression.

- Operating Range: Typically –20°C to +70°C for PP/PVC; up to +120°C for nylon.

- Standards: Custom frames may meet industrial specifications (e.g., UL 94, ISO 1182).

Unique Selling Points (USPs)

- Enhanced Environmental Resistance: Plastic frames are impervious to moisture and chemicals, making them ideal for outdoor equipment.

- Versatile Fabrication: Easily thermoformed or welded for custom shapes (e.g., right-angle joints, integrated clips).

- Low Thermal Conductivity: Unlike metal frames, plastic frames do not conduct heat, beneficial in thermal insulation assemblies.