Key Features

- Corrosion & Rust Proof: Nonmetallic PVC material resists chemicals, salt air, and water exposure.

- Sunlight Resistant: UV inhibitors allow safe sunlight exposure without brittleness.

- UL/NEMA Certified: Meets UL 651 and NEMA TC-2 standards; generally 90°C rated for hot wires.

- Schedule 40/80 Options: Standard (40) or heavy-duty (80) wall thickness for different mechanical strength requirements.

- Easy Installation: Light enough to handle manually; solvent weld or threaded fittings are used for connections.

Benefits

- Low Maintenance: Unlike metal conduits, PVC never needs painting or rust-proofing.

- Cost Savings: Generally lower material and labor cost than metal; no need for grounding of conduit.

- High Insulation: Smooth inner surface reduces wire friction; PVC is insulating for electrical safety.

- Longevity: Designed for 25+ years of life in harsh environments, per industry standards.

Applications

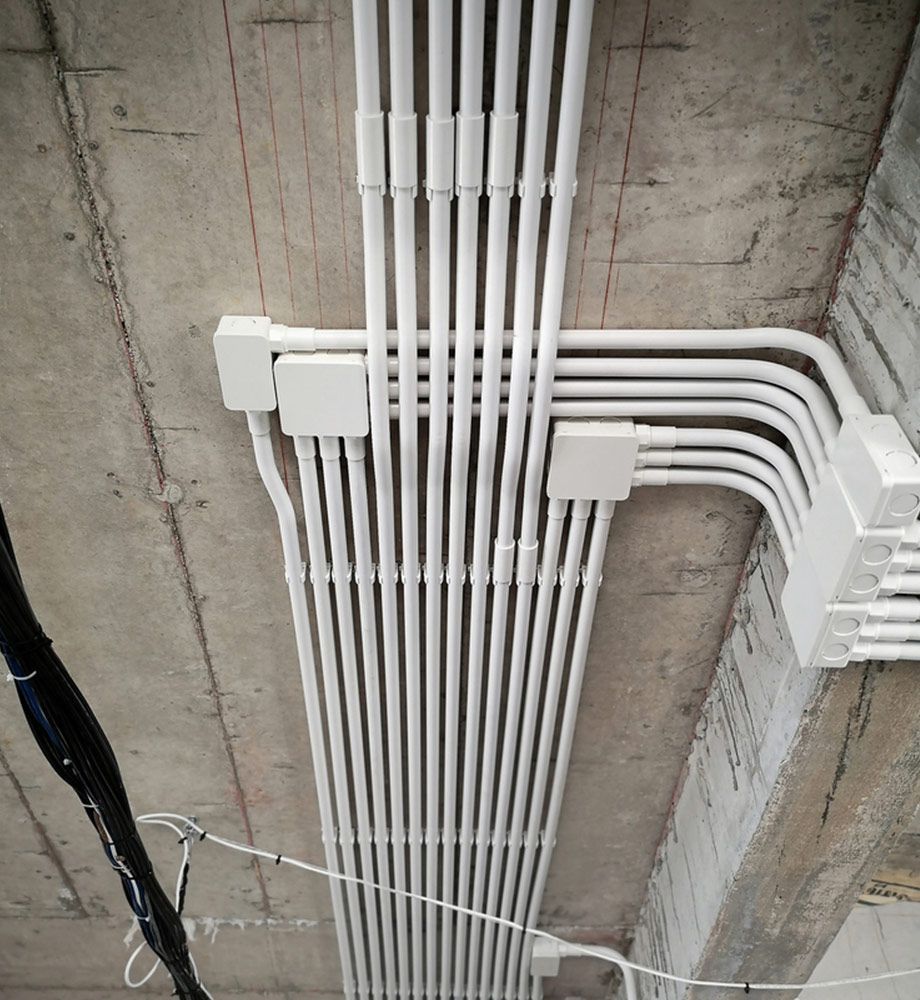

- Commercial & Residential Wiring: Raceway for electrical branch circuits in walls, ceilings, and buried applications.

- Industrial Facilities: Cable routing for factory automation, control systems, and MCCs (in clean areas).

- Data and Telecom: Protecting fiber-optic and network cables outdoors or between buildings.

- Solar & Renewable Energy: Conduit runs for PV system wiring, battery enclosures.

Technical Specifications

- Standards: Conforms to UL 651, CSA C22.2 No. 211.2, NEMA TC-2.

- Temperature Rating: Usually –20°C to +60°C for normal PVC (higher temps for PVC-O or CPVC).

- Lengths & Sizes: Common lengths are 10-foot sections; diameters from ½″ to 4″ (and larger for Schedule 40/80).

- Color: Typically gray for electrical (other colors for other uses, e.g. white, yellow).

Unique Selling Points (USPs)

- Proven Durability: Widely used for decades with demonstrated UV and chemical stability.

- Ease of Use: No special tools needed (vs. threading metal); cuts with basic saws and glues.

- UL-Listed Quality: Ensures compatibility with electrical codes and safety requirements.