Key Features

- High Fiber Content: Typically 60–80% fiber by volume (E-glass, sometimes carbon).

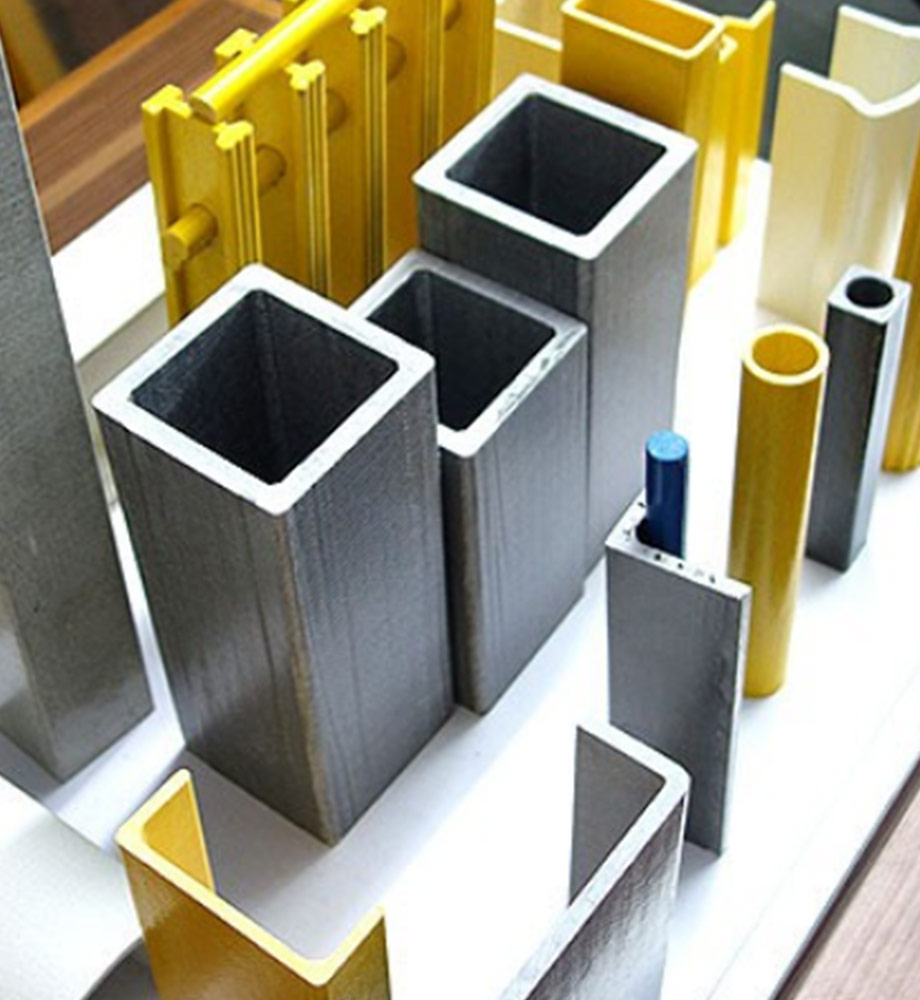

- Standard Profiles: C-channels, I-beams, L-angles, tubes (rectangular/round), flat bars, custom shapes.

- Consistent Quality: Pultrusion yields tight dimensional tolerances and uniform mechanical properties along the length.

- Resin Options: Polyester, vinylester or epoxy matrices available for specific fire/chemical resistance requirements.

Benefits

- Corrosion & Chemical Resistance: Fiberglass profiles will not rust in marine or humid environments, giving a long service life with minimal maintenance.

- High Strength-to-Weight Ratio: Pultruded parts can carry heavy loads (e.g. roof panels, walkways) while being much lighter than steel.

- Low Thermal Expansion: Minimal movement with temperature changes, maintaining structural stability.

- Ease of Machining: Can be drilled, cut and notched on-site without special tools.

Applications

- In wind turbines, pultruded sections are used for ladder rails, platform girders, internal supports, electrical troughs, and even tower cross-bracing in hybrid designs. They are also used in support structures at wind farms (offshore platforms, substation walkways, catwalks). Pultruded FRP decks or beams are a popular alternative to steel grating for service platforms.

Technical Specifications

- Pultruded profiles are offered in lengths up to 12 m or more, with sectional dimensions designed to match standard industrial sizes. Typical mechanical properties: Tensile modulus ~20–50 GPa, tensile strength ~200–500 MPa (depending on fiber). Profiles can be manufactured in fire-retardant grade (UL 94 V0) and meet ASTM standards (e.g. ASTM D3916 for FRP pultrusions).

Unique Selling Points (USPs)

- We stock a wide variety of FRP profiles and can also custom-pultrude shapes. Our pultrusions undergo ISO 9001 quality control and in-house testing. Compared to metal, these sections resist abrasion and chemical attack – for instance, FRP cable trays made from pultruded material are “extremely durable and resistant to chemical attack”. By using pultruded FRP in towers and platforms, our clients extend lifecycle and lower maintenance costs.