Key Features

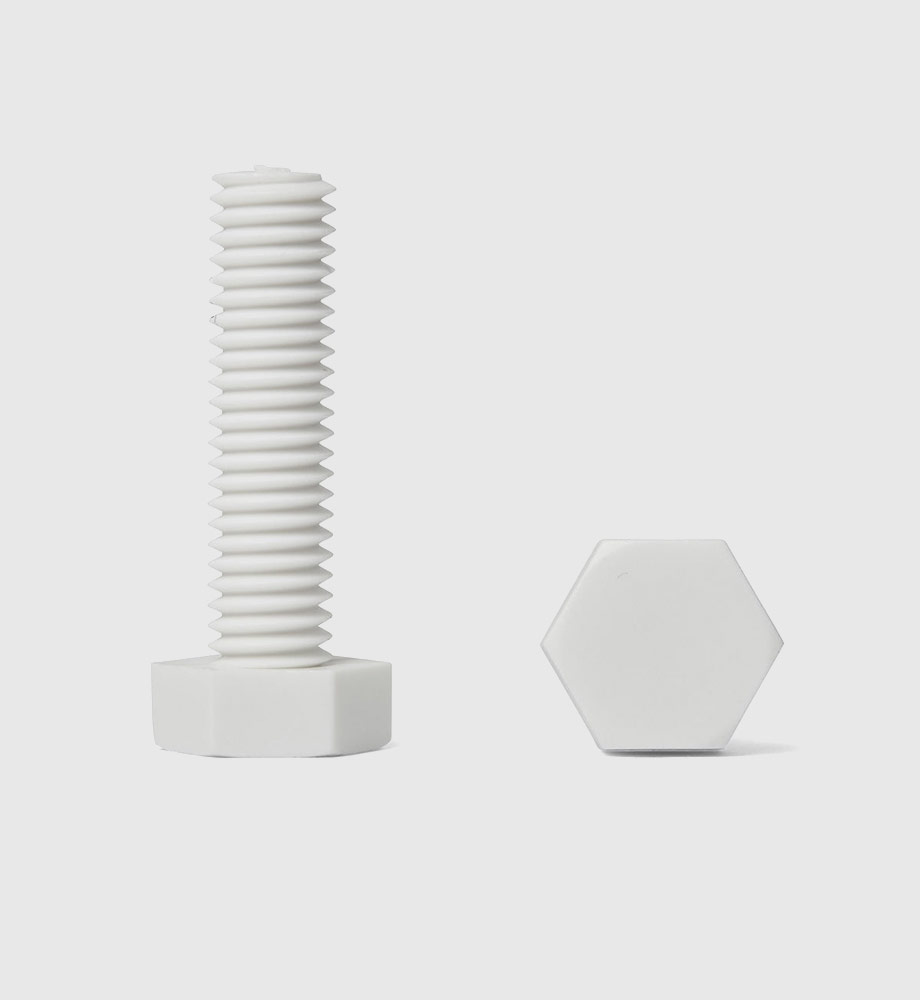

- Non-Conductive Insulating Hardware: Nylon fasteners provide electrical insulation, preventing shorts.

- Corrosion Resistance: Unaffected by moisture, chemicals, or salt air.

- Broad Range: Includes helical threaded inserts for plastics, self-threading screws, locking nuts, standoffs, spacers, and rivets.

- High Strength (Nylon): Good tensile and shear strength for many structural applications.

- Self-Locking Options: Nylon lock nuts with embedded nylon rings resist loosening under vibration.

Benefits

- Lightweight: Reduces overall weight of assemblies, important in transportation and appliances.

- No Galling: Plastic threads won’t gall like metal, making for smoother torque.

- Reusable: Nylon lock fasteners can often be used multiple times with minimal wear.

- Cost-Effective: Less expensive than specialty metal hardware in corrosive or high-volume uses.

Applications

- Electronics: Circuit board mounting standoffs, insulating bushings for PCB screws.

- Pipelines and Valves: Plastic flange fasteners in chemical pumps or filtration systems.

- Medical Equipment: Non-metallic screws and nuts in devices where MRI compatibility or corrosion is an issue.

- Consumer Products: Nylon bolts in appliances, furniture assemblies, or fixtures.

Technical Specifications

- Materials: Nylon 6/6 (common), Nylon 6, Polypropylene (for less load-bearing needs).

- Thread Standards: Metric (M#), UNC/UNF for standard compatibility.

- Strength: Nylon 6/6 can achieve tensile strength ~8,000 psi (≈55 MPa).

- Temperature: Nylon fasteners: –40°C to +85°C typically; PP: –20°C to +80°C.

Unique Selling Points (USPs)

- Electrical Safety: Nylon fasteners are inherently insulative and corrosion-proof, ideal for sensitive electronic enclosures.

- Chemical Compatibility: Polypropylene inserts can be used in contact with aggressive fluids where metals fail.

- Vibration Damping: Plastic hardware absorbs shock and vibration without loosening.