Key Features

- Bi-Directional Load: Strength in both the longitudinal and transverse directions for uniform support.

- High Corrosion Resistance: Gel-coated or vinyl-ester resin options protect against salt spray and chemicals.

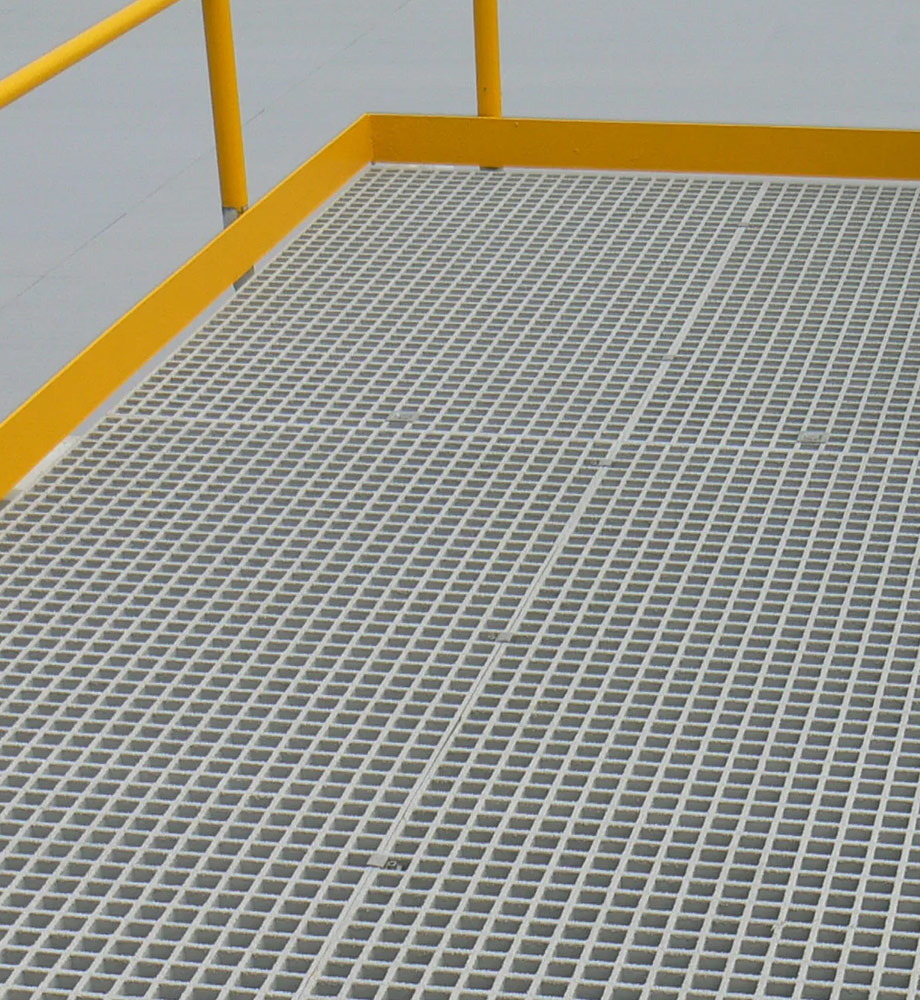

- Non-Slip Surface: Textured topside (grit or serrations) for traction, plus ergonomic grating patterns.

- Customizable: Available in various depths (20–50 mm), mesh sizes, and colors; panels cut-to-size or factory preassembled.

Benefits

- Lightweight and Strong: Reduces dead load on structures while safely supporting personnel and equipment.

- Safety: Non-conductive, fire-retardant (per UL 94 V-0), and slip-resistant – improving workplace safety on platforms.

- Low Maintenance: Unlike steel gratings, FRP gratings will never rust or rot. Their “corrosion-resistant properties” make them “a long-lasting, virtually maintenance-free solution” in corrosive applications.

- Compliance: Can meet ADA (Americans with Disabilities Act) standards for floor openings and loading (13 mm ball test).

Applications

- Used as flooring on turbine maintenance platforms, offshore substation decks, tower ladders landings and any elevated walkway. Also suitable for cable trench covers and drain grates around turbine bases.

Technical Specifications

- Standard panels are 1.2 m × 3.6 m or 1.25 m × 2.5 m, with mesh sizes from 12.7×12.7 mm to 38×38 mm. Load ratings: typical uniform load capacity >5 kN/m² for 25 mm thick panels. Grating is UL94 V-0 rated, ASTM E84 Class 1. Temperature range: –60°C to +80°C (with special resins for higher temps).

Unique Selling Points (USPs)

- Our molded gratings are supplied by leading manufacturers (Fibergrate, Bedford, etc.) and are proven in the offshore wind industry. For example, America’s first offshore wind farm used FRP grating on its operations platform due to superior durability. We provide anti-slip coated surfaces and ADA-compliant options (such as Micro-Mesh® gratings). Custom trays and stair treads can be integrated for complete platform systems.