Key Features

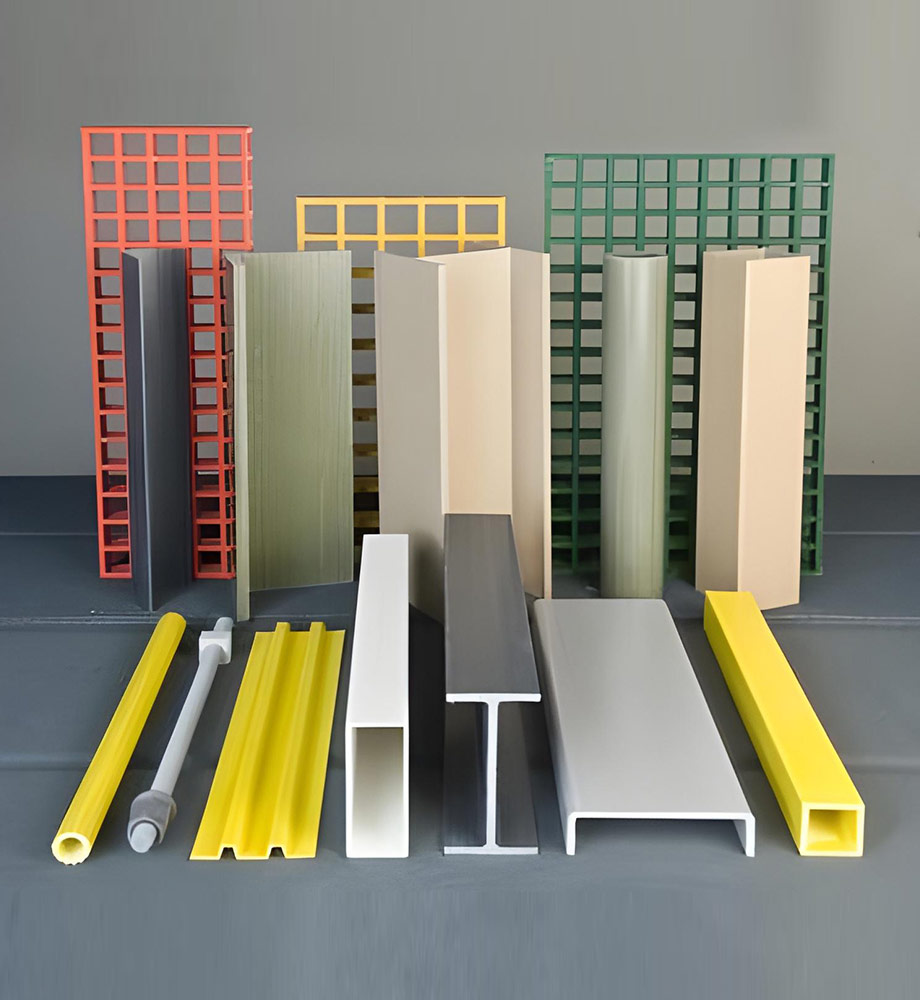

- High-Strength FRP Shapes: Pultruded profiles tailored for specific loads.

- Non-Corrosive: 100% fiberglass, often UV-protected.

- Slip-Resistant Grating: FRP grating with molded safety surfaces.

- Fire-Retardant Options: Marine-grade or fire-retardant resins available.

Benefits

- Maintenance-Free: No need for coatings or sanding; lasts for decades in outdoor FGD yards.

- Lightweight: Easier to install/modify; reduces structural loading.

- Electrical Insulation: Non-conductive nature adds safety for personnel.

Applications

Used for walkways around scrubbers and ducts, support structures for equipment, and platforms for pumps and fans. FRP ladders and handrails ensure safe access to FGD vessels. Structures can be fully engineered to meet seismic or snow loads.

Technical Specifications

- Standards: Compliant with FRP structural design guides (ASTM D610, ACI 440).

- Surface Finish: UV-stable gelcoat (for outdoor) or polyester paint (for indoor).

Unique Selling Points

Our FRP structures are custom-designed for FGD plants. We offer integrated grating and supports that bolt directly to FRP equipment. Because they are engineered composites, our structural components outlast wood and outperform steel in the acidic environment of FGD.