Key Features

- Corrosion-Resistant Construction: Won’t rust, rot or corrode (even in saltwater or acidic conditions).

- High Strength-to-Weight Ratio: Fiberglass pultrusion yields components that are as strong as steel or wood but much lighter.

- Virtually Maintenance-Free: Durable resin and UV-stabilized fibers eliminate the need for painting, galvanizing or replacement.

- Fire-Retardant & Non-Conductive: Naturally electrical-insulating; fire-resistant resins can be used to meet flammability standards.

- Dimensional Stability: Won’t warp, creep or swell under load; maintains shape and straightness over time.

- Uniform Quality: Pultrusion produces highly consistent cross-sections and properties from piece to piece.

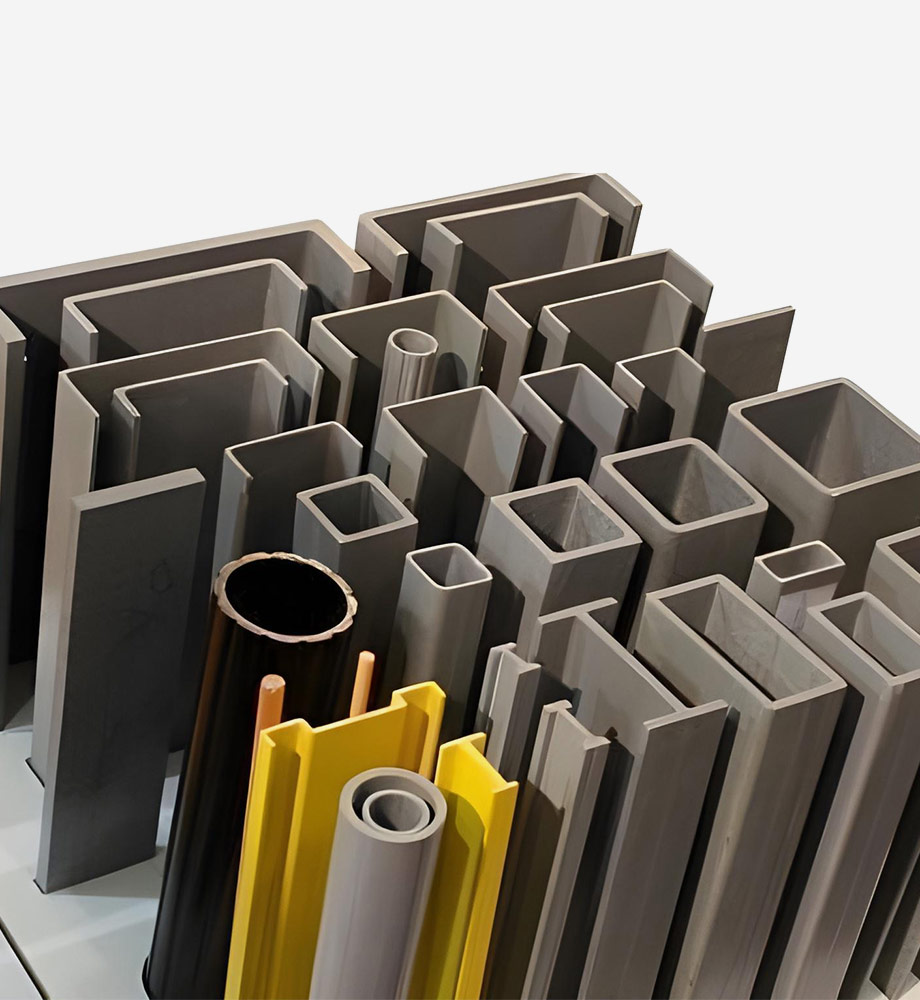

- Versatile Profiles: Standard shapes include channels (C, U), I-beams, angles, square/round tubes, flat sheets, rods and baffle panels. (Custom profiles can be pultruded to spec.)

- Custom Color & Finish: Available in multiple colors (e.g. safety yellow, gray, tan) for high visibility or aesthetic integration.

Benefits

- Extended Service Life: FRP profiles last far longer than wood or metal in harsh environments (often 25+ years warranty).

- Lower Lifecycle Cost: No corrosion repairs or coatings needed; minimal inspection/maintenance lowers operating costs.

- Reduced Structural Load: Lighter components mean smaller foundations and support structures (saves on steel and concrete).

- Safety and Conductivity: Non-conductive material enhances safety in electrical and telecom applications by insulating against stray currents.

- Rapid Assembly: Components can be pre-drilled or easily fabricated on-site, allowing quick construction with common tools.

- Consistent Performance: Factory-controlled manufacturing ensures each profile meets stringent quality specifications.

Applications

- Structural Frames & Supports: Platforms, walkways, guardrails, and supports in chemical plants, wastewater facilities, cooling towers and offshore structures.

- Infrastructure & Buildings: Beams and columns in architectural constructions (e.g. viewing platforms, pavilions) where corrosion is a concern.

- Oil & Gas Installations: Cross-members, braces and pipe supports in refineries and marine oil terminals (salty, humid environments).

- Utility Structures: Substation cable supports, concrete embedment angles, and foundations for telecom towers (non-corrosive under ground).

- Process Piping: FRP channel and angle supports that hold piping in corrosive process areas.

- Agricultural & Mining: Structural shapes in irrigation systems, mine shafts and geotechnical supports (resistant to soil chemicals).

- Custom Fabrications: FRP beams, cross-arms and structural frames for specialty equipment (pump stands, separators, racks) where metal alternatives fail.

Technical Specifications

- Material: Continuous fiberglass roving in polyester or vinylester resin matrix (with options for vinylester/polyester suited to the chemical environment).

- Profile Sizes: Channel widths from ~50 mm up to 300 mm (or more); beam heights up to ~400 mm; tubes from Ø20 mm to Ø200 mm. Lengths typically 6–12 m (cut to order).

- Mechanical Properties: Tensile strength ~240 MPa; flexural modulus ~20 GPa (typical pultruded FRP values). Design guides available for load capacity and deflection.

- Thermal & Electrical: Low thermal conductivity (~0.5 W/m·K) and very high dielectric strength (>15 kV/mm) – suitable for insulating supports.

- Fire Rating: Many FRP shapes can achieve Class 1 flame spread (ASTM E-84) with fire-retardant resin systems.

Unique Selling Points (USPs)

- Proven Durability: Our FRP profiles come with industry-leading warranties (20+ years) and have decades of proven performance.

- One-Stop Supplier: A comprehensive stock of standard shapes, plus in-house custom pultrusion, means we can supply any needed profile quickly.

- Multi-Color Options: For safety and design flexibility, profiles can be pultruded in any RAL color, including custom or safety hues.

- Cutting-Edge Materials: We offer premium resin formulations (e.g. Super Vi-Corr®, ELS low-smoke) to tailor corrosion and fire performance.

- Lightweight Advantage: The low weight and ease of handling of FRP shapes drastically reduce installation time and cost.

- Environmental Safety: No need for chemical wood treatments or metal coatings – FRP is inherently inert and more sustainable in life-cycle impact.