Key Features

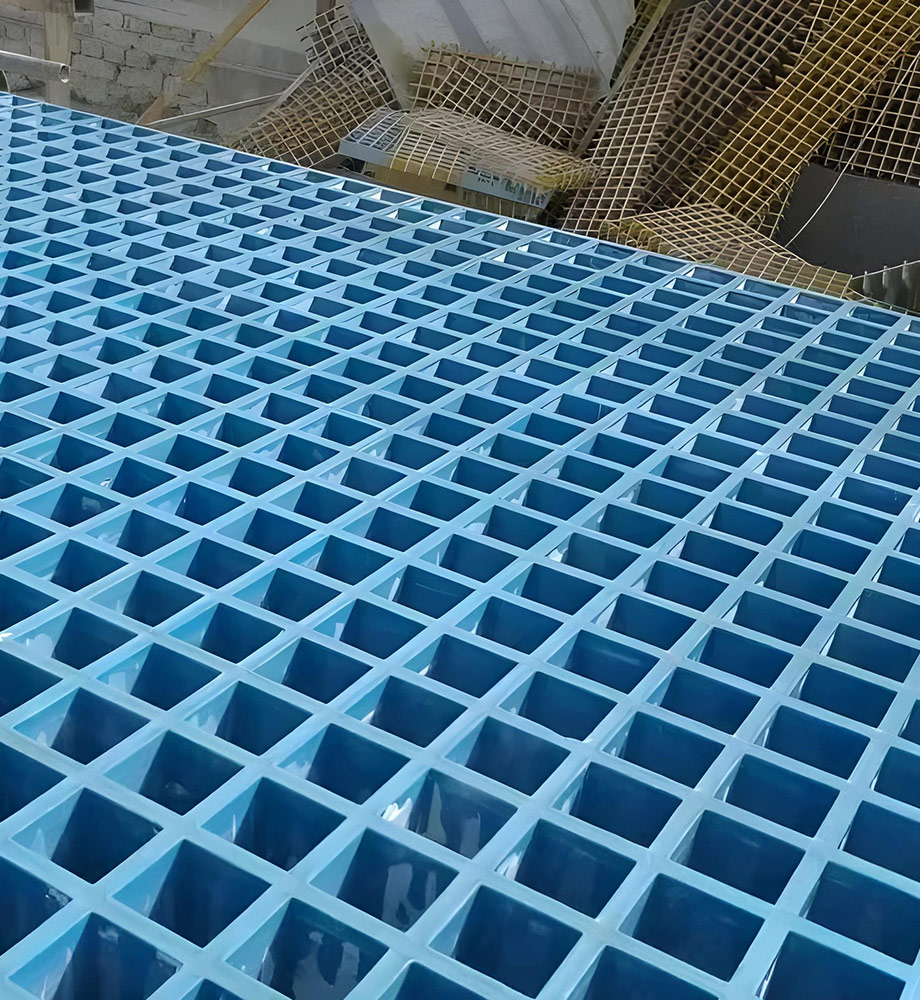

- Uniform air/gas distribution via perforated FRP headers.

- Corrosion-resistant fiberglass construction for long life in alkaline slurry.

- Custom layouts match tank geometry and flow needs.

- Optionally dual-laminate (e.g. PP-lined) for very aggressive chemistries.

Benefits

- Efficient Oxidation: Ensures complete conversion of sulfite to sulfate, maximizing SO₂ removal and gypsum quality.

- Low Blockage Risk: Smooth FRP surfaces resist scaling; design provides easy inspection/cleaning.

- Cost Savings: Longer life and reliability than steel spargers, avoiding frequent replacements.

Applications

Used in wet FGD absorbers (limestone/gypsum processes) to distribute oxidation air or process gases. FRP sparger grids are also employed in other scrubbers where uniform reagent dispersion is needed (e.g. seawater FGD oxidation). These systems improve flow uniformity in large absorption tanks.

Technical Specifications

(Example) FRP Air Sparger – custom-designed for 3–20 psi air supply; standard FRP grades vinyl ester resin; lined options available; sizes per reactor.

Unique Selling Points

Our FRP sparger grids are engineered for precise airflow patterns. We use proprietary fabrication (e.g. filament winding) to produce heavy-duty grids that withstand thermal and pressure cycling. Combined with FRP risers and internal piping, our sparger systems create a fully FRP circulation network that avoids any metal contact.