Key Features

- High Efficiency: Removes fine mist and aerosols (>99% droplet capture).

- Corrosion-Resistant FRP: Ideal for acid gas scrubbers and harsh environments.

- Low Pressure Drop: Engineered vane geometry or mesh to minimize energy loss.

- Modular Design: Packable sections that fit any scrubber cross-section.

- Easy Maintenance: Fiberglass doesn’t swell or corrode; mesh pads can be washed.

Benefits

- Protects Downstream: Prevents corrosive or toxic droplets from damaging fans, ducts or emitting into the air.

- Improves Performance: Keeps scrubber packing dry, maintaining high gas-liquid contact efficiency.

- Long Service Life: FRP withstands continual wetting and chemical exposure far better than metal.

- Cost Savings: Less frequent replacement than metal demisters in corrosive service.

Applications

- Wet Scrubbers: Final stage mist eliminators in gas scrubbers (acid gas, ammonia, chlorine, etc.).

- Cooling Towers: Drift eliminators (similar function) in FRP cooling tower pack.

- Chemical Reactors: Emissions treatment to capture solvent or acid mists.

- Odor Control: In wastewater headworks (removing odorous aerosols).

Technical Specifications

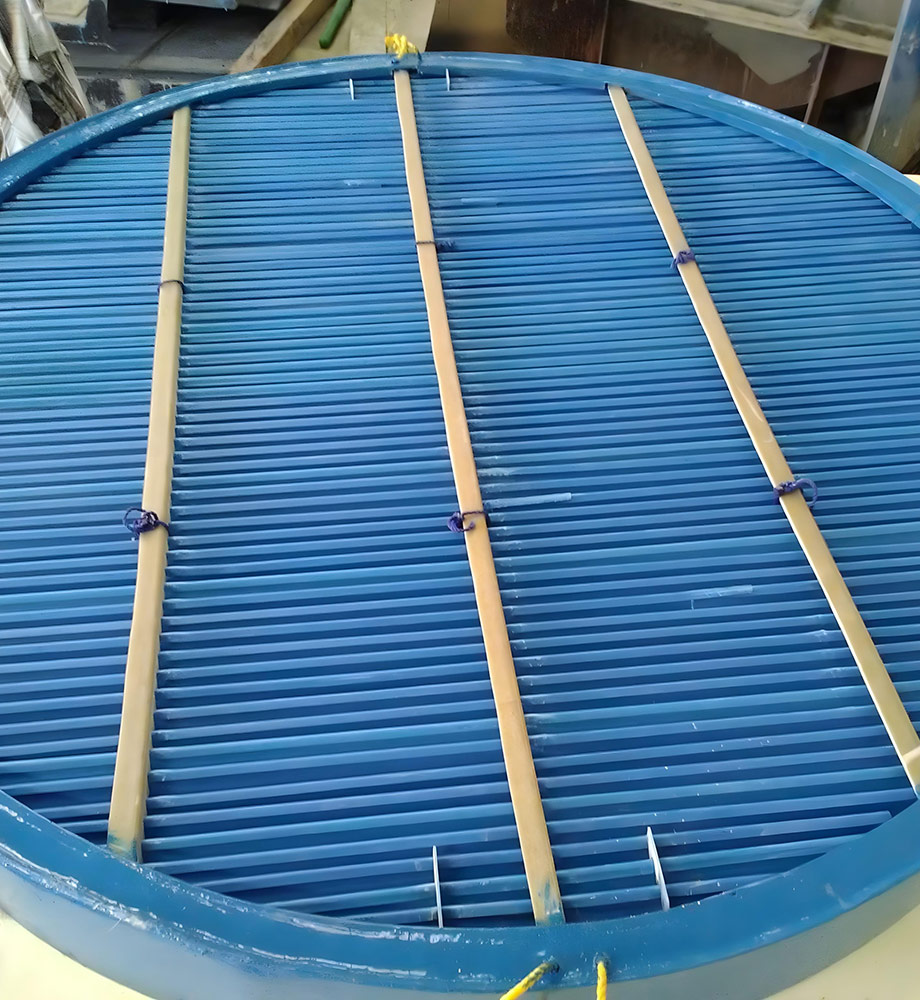

- Configurations: Chevron (thin sheet vanes) or mesh (woven/vinyl pads).

- Materials: FRP for frames; internals often PP or similar, supported by FRP.

- Efficiency: ≥98% removal at design velocity (achievable by design).

- Pressure Drop: Typically 20–80 Pa (depending on velocity and style).

Unique Selling Points

- Maximum Removal: Designs that “ensure mist removal efficiencies often approaching 100%”.

- FRP Durability: Unlike plastic mesh, FRP vanes are mechanically robust.

- Chemical Resistance: Tolerates bleach, acids or alkalis common in treatment exhaust.

- Lightweight Packs: Easy to retrofit into existing systems for upgrades.