Key Features

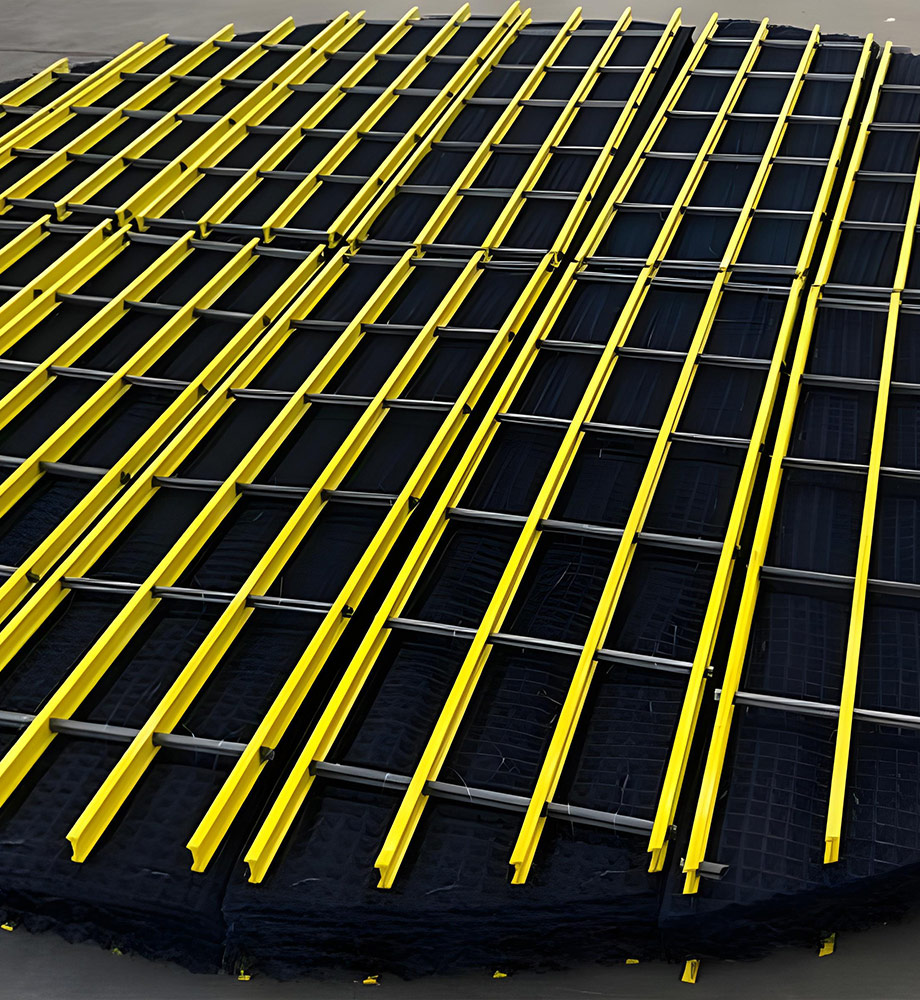

- Vane Pack Construction: Series of FRP vanes or mesh layers assembled in a frame.

- Corrosion-Resistant: Entire assembly (frames and internals) made of fiberglass, PP or PVC.

- Low Pressure Drop: Engineered vane angles minimize gas flow resistance.

- Modular Panels: Standard panel sizes fit within the vessel or ductwork.

Benefits

- High Efficiency: Removes >99% of liquid entrainment, ensuring clean gas discharge.

- Zero Maintenance: No corrosion means no periodic replacement as with steel vane packs.

- Compact Design: FRP’s strength allows thin panels; space-effective demisting.

Applications

Installed at the top of wet scrubber towers (before the stack) to eliminate slurry droplets. Also used in any gas-liquid separation stage of FGD (e.g. downstream of venturi scrubbers or spray towers). FRP mist eliminators are ideal for sea-water FGD or lime systems, where stainless steel would fail.

Technical Specifications

- Materials: FRP, polypropylene (PP), or PVC. Frames in FRP or stainless steel (316L optional).

- Sizes: Panel dimensions up to 4’×10’ or larger as needed; assembled on-site for large areas.

Unique Selling Points

Our FRP demister pads are specially designed for FGD conditions. We ensure all wetted components are FRP/PP to prevent corrosion. Panels are framed in an all-FRP structure with 316SS hardware as required. The result is a demister system that outperforms metal designs in durability and cost over the plant’s lifetime.