Key Features

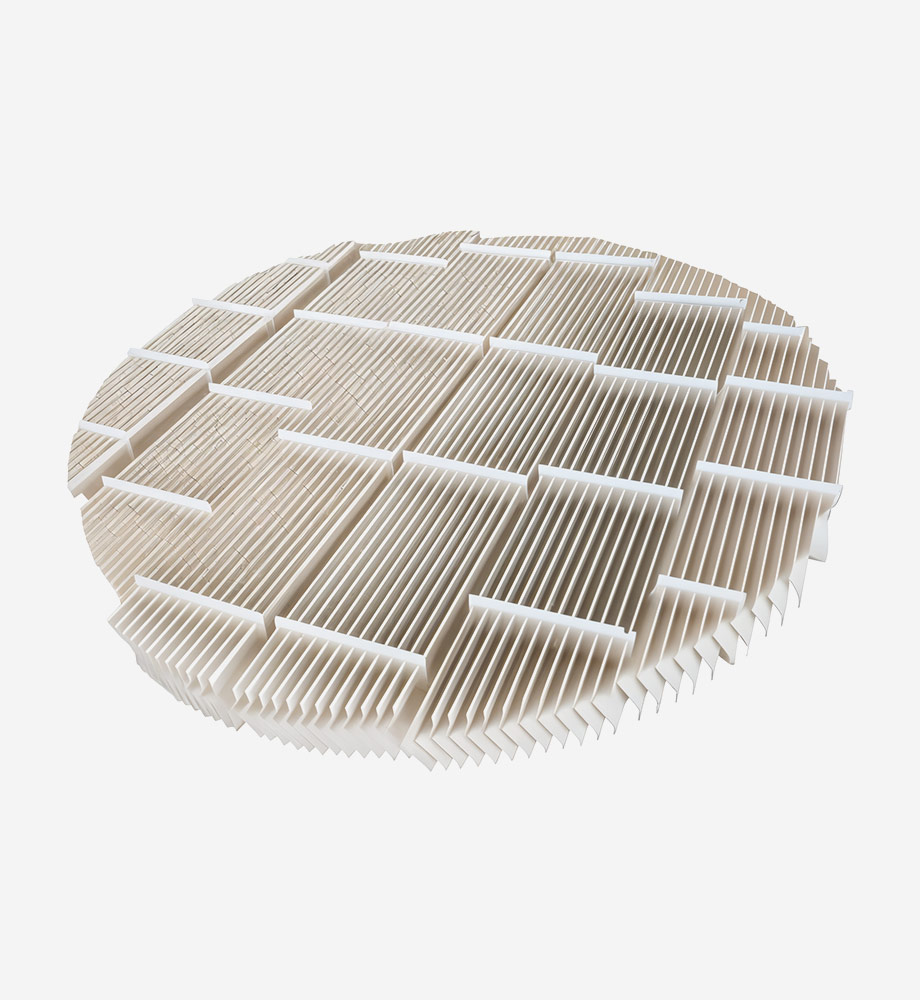

All-FRP housing or frame; support for polyester, polypropylene or nylon mesh; optional PTFE-coated mesh for high-temp or oily conditions. Pressure drop is minimized by optimizing element length and spacing.

Benefits

Extends equipment life by preventing liquid carryover, ensures compliance with emission limits. FRP construction means units can be located outdoors or in corrosive ventilated areas without rust.

Applications

Mist eliminators are used in chemical scrubbers, evaporators, incinerator stacks and any process vent where entrained liquids must be removed (metal finishing, power plants, oil & gas flares, wastewater odor control).

Technical Specifications

Media efficiency (>99% for >10 µm droplets typical), pressure drop <2″ H₂O. FRP frames comply with NSF/ANSI 61 if used on potable systems.

Unique Selling Points

Our FRP mist eliminators are custom-designed for each scrubber, ensuring perfect fit. We use high-strength FRP panels that support media layers without deformation. Compared to welded steel units, these need no painting or anodes and have much lighter weight.