Key Features

- High strength-to-weight: Glass-fiber construction gives excellent load-bearing capacity while remaining lightweight.

- Corrosion/Chemical Resistance: Won’t rust or corrode; resists most acids, alkalis and solvents.

- Fire-Retardant Options: Available with special resins (e.g. ASTM E84 flame spread ≤25) for fire-safe applications.

- Slip- and Impact-Resistant: Grit or concave surfaces prevent slipping; resilient under impact or heavy traffic.

- Bi-/Uni-zirectional Strength: Molded panels carry loads uniformly in two directions; pultruded sections provide exceptional unidirectional span in the bearing bar direction.

- Easy Fabrication/Installation: Panels can be cut, drilled or trimmed on-site with common tools, and are supplied with matching clamps and fixtures.

- Non-Conductive & Non-Sparking: Ideal for electrical safety and explosive atmospheres (no arcing or magnetism).

Benefits

- Long Service Life: FRP grating does not corrode or fatigue easily, so it outlasts steel or wood gratings with minimal maintenance.

- Low Maintenance Cost: Simple periodic cleaning is usually sufficient; repairs or replacements are rarely needed.

- Improved Safety: Slip-resistant surface and absence of sharp edges reduce fall hazards; non-conductive material prevents electrical shock.

- Cost-Effective: Lower life-cycle cost through extended lifespan and fewer support steel sections (lightweight spans reduce structure size).

- Quick Installation: Light panels speed up installation and reduce labor; bi-directional molded panels often require no extra framing for cutouts.

Applications

- Industrial Flooring & Walkways: Platforms, stair treads and elevated walkways in chemical plants, power plants, mining, pulp & paper, steel mills and factories.

- Marine & Corrosive Environments: Docks, marina ramps and offshore platforms where saltwater and chemicals are present.

- Oil & Gas Facilities: Drilling rigs, refineries and processing plants (high strength, flame retardancy and chemical resilience).

- Water/Wastewater Treatment: Gratings for tanks, trenches and covers that resist acids, chlorine and other treatment chemicals.

- Architectural & Commercial: Pedestrian bridges, stadium walkways, rooftop access (durable outdoor flooring that requires minimal upkeep).

Technical Specifications

- Panel Size: Standard panels up to 4’×12’ or larger; custom lengths and widths are available.

- Thickness & Mesh: Common thicknesses range from ~1″ (25 mm) to 1½″ (38 mm); mesh patterns (e.g. 1″×1″, 1½″×1½″) vary by load rating.

- Resin Systems: Polyester or vinylester resins (with optional corrosion-resistant vinylester gelcoat); XFR/ELS resins for extra fire/smoke performance.

- Load Capacity: Engineered to meet specified design loads (e.g. ladder grade vs heavy duty); typical load ratings up to several thousand pounds per square foot in the bearing bar direction.

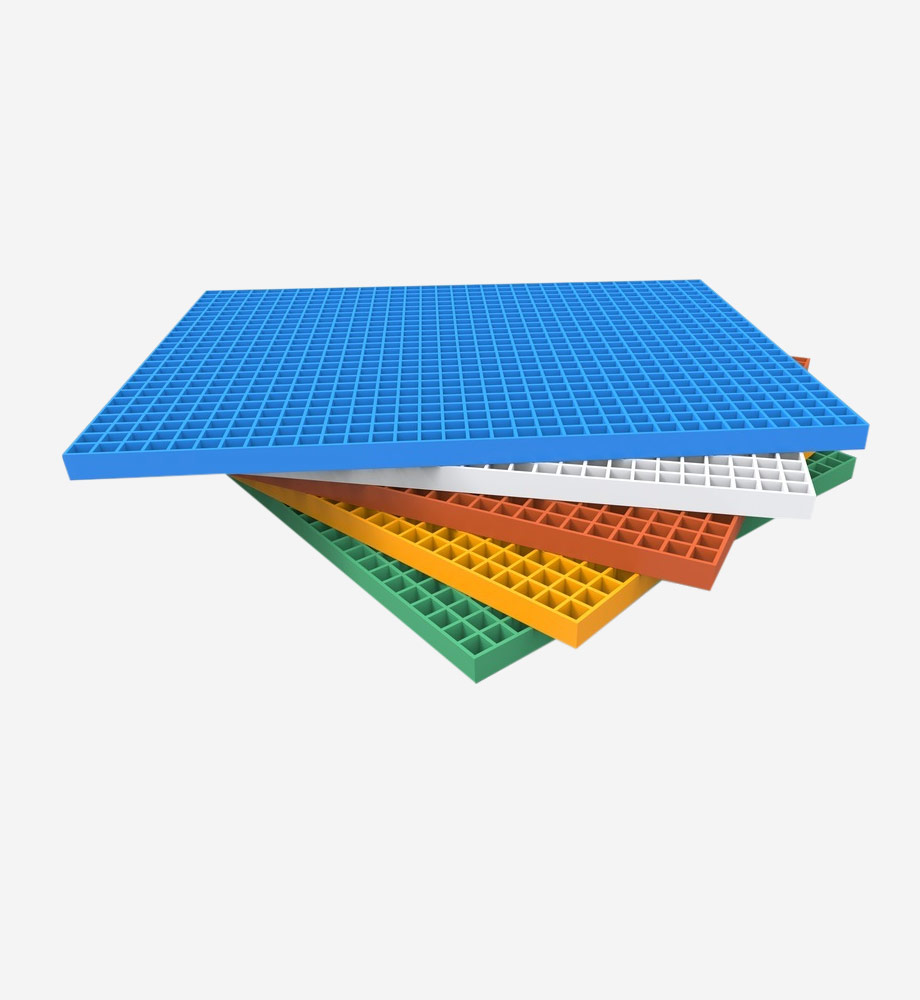

- Colors: Often stocked in safety yellow, gray or green; virtually any RAL color or translucent option can be custom-matched.

Unique Selling Points (USPs)

- Bidirectional Strength (Molded) vs. High-Span Pultruded: Combines the best of both technologies for any application. Molded panels support multi-directional loads; pultruded sections achieve longer spans with high edge strength.

- Exceptional Fire/Safety Ratings: Flame-retardant variants (ASTM Class 1) and high-surface-grit options set them apart from standard polymer gratings.

- Long Warranty and Proven Life: FRP gratings often come with 10+ year warranties (some manufacturers offer 10–25 years) and have proven multi-decade lifetimes.

- Complete Support Accessories: Full range of FRP clamps, standoff blocks, trims and hardware are available for fast, secure installation.

- Custom-Fabrication Expertise: Profiles can be manufactured in unusual sizes, cutouts and shapes to meet exact site requirements without extensive steelwork.