Key Features

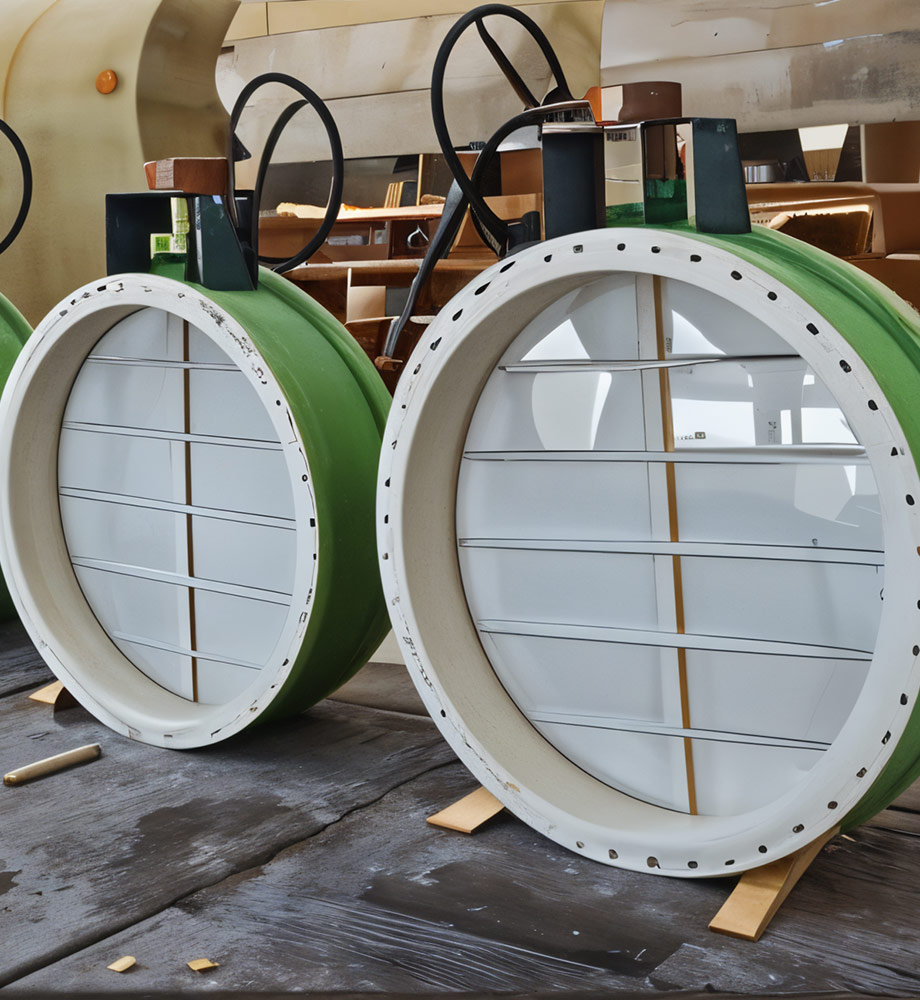

- All-FRP Construction: The valve body and blade are molded FRP (vinyl ester resin), preventing any part from rusting in acidic or humid airstreams.

- Actuation Options: Blades can be operated by handwheel, gearbox, pneumatic cylinder or electric actuator. Gear trains are designed so that a seized blade does not overload the actuator.

- Teflon Bearings: Self-lubricating Teflon bushings on the shaft guarantee smooth operation and long life, even with corrosive vapors present.

- UV-Protected Finish: Exterior coatings or UV-stable resins prevent sun-degradation for outdoor dampers.

Benefits

- Corrosion Immunity: Unlike steel dampers that seize up, FRP dampers stay functional in aggressive exhaust (acid pickling lines, HCl gas flows, flue vents).

- Reliability: The robust FRP design means leakage is extremely low when closed (good for shutdown isolation). The Sunrise example notes that FRP dampers “outperform conventional butterfly dampers”.

- Safety: FRP dampers contribute to safer maintenance conditions. They provide full shutoff in dangerous ducts, and their non-sparking nature is ideal for explosive environments.

- Low Maintenance: No lubrication of the FRP parts is needed. External access to bearings means they can be serviced without dismantling the unit.

Applications

FRP damper valves are used in industrial ventilation, fume exhaust, scrubber vent lines, boiler air intakes, and anywhere corrosive airstreams are present. They are commonly specified in chemical plants, petrochemical units, and marine exhaust systems. Wherever a damper must operate with sulfuric acid, caustic, salt air or other solvents, FRP dampers provide a worry-free solution.

Technical Specifications

Damper sizes range from small (4″) to very large (120″) diameters. They meet standards like ASME RTP-1 for fire-side service. Temperature ratings depend on resin (e.g. vinyl ester FRP to ~150°C). Damper leakage class is typically Class V (zero leakage) when used with sealed flanges. Gearbox operators follow API linkage classes (I–VI) as needed.

Unique Selling Points

FRP damper valves stand out for their long life in toxic environments. A unique feature is the use of external Teflon bearings (no need to open the duct to replace them). They also provide increased process safety: by isolating hazardous streams without corroding, they reduce the risk of ductwork leaks during shutdowns. Compared to any metal damper, the FRP damper’s unique advantage is absolute corrosion resistance and minimal life-cycle cost (no paints or coatings to renew).