Key Features

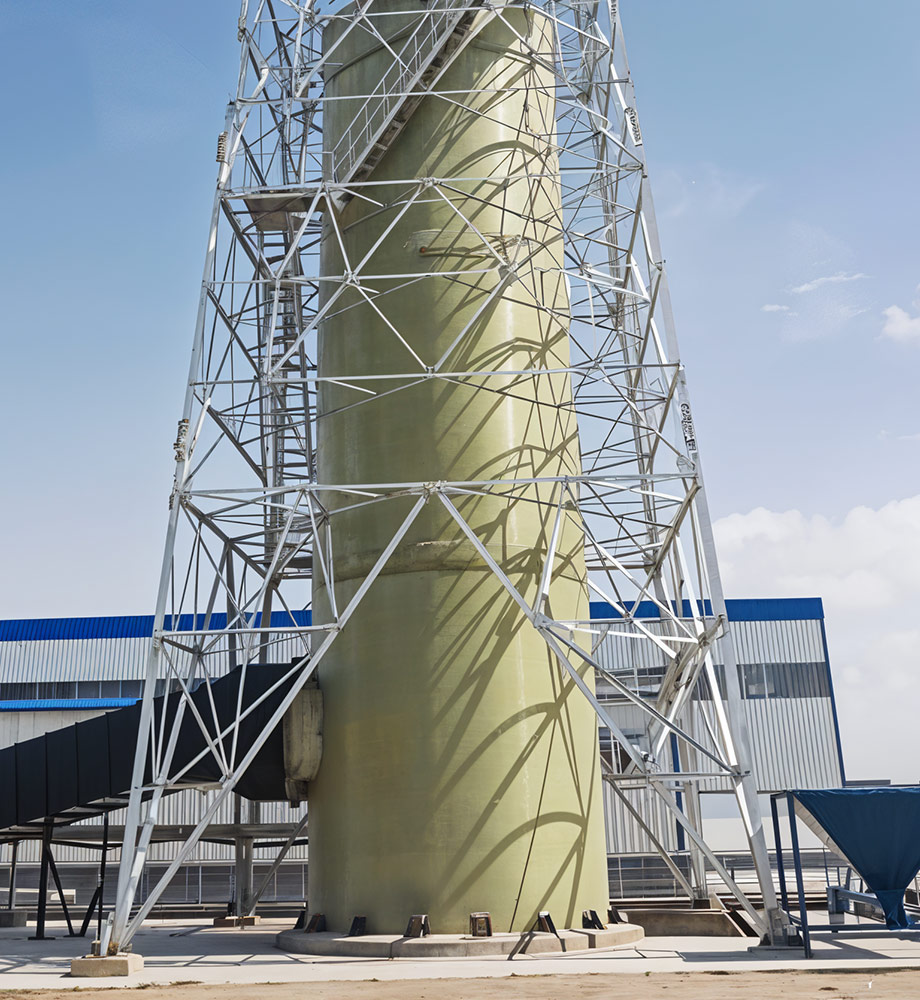

- Lightweight Construction: FRP stack sections weigh only a fraction of steel, making handling and erection easier (often by crane lifting preassembled sections).

- High Corrosion Resistance: The FRP resin and glass layup resists sulfuric acid, chlorides, salts, and other corrosive agents in flue gas. The smooth interior prevents buildup and maintenance headaches.

- High Strength & Rigidity: Despite the light weight, these stacks meet structural requirements for wind and earthquake loads. They remain stable even at heights.

- Quick Installation: Modular sections bolt or flange together; no on-site concrete or heavy foundations are required (self-supported or guyed designs are available).

- Weatherproof and UV Resistant: The composite resins provide longevity in outdoor conditions without needing repainting.

Benefits

- Long Service Life: Typical FRP stacks last for decades with minimal degradation. This dramatically reduces total cost of ownership versus carbon steel (which rapidly rusts) or lined steel.

- Low Maintenance: No steel supports means no corrosion points. FRP stacks do not require protective linings, and inspections/repairs are infrequent.

- Design Flexibility: Stacks can be built in diameters from under 1m to over 4m, and heights from a few meters up to 50+ m. Shapes can be straight, tapered, or satellite (offset) to avoid obstacles.

- Economical: FRP stacks often have lower installation cost than tall steel flues, since no lifting lugs or scaffolding for heavy plates are

Applications

FRP chimneys are widely used in power generation (coal, gas, biomass), cement plants, oil & gas refineries, waste-to-energy facilities, fertilizer production, and chemical plants. They are especially popular in offshore oil/gas platforms and marine exhausts (where salt spray corrodes metal). FRP stacks are ideal for high-temperature or corrosive flue gases—for example, venting SO₂-containing flue gas from a sulfuric acid plant or HCl from a plastics plant.

Technical Specifications

Typical FRP stack sections are available in thicknesses (laminate schedule) engineered for the application. Specifications often cite service temperature limits (e.g. up to 150°C for certain vinyl ester resins) and chemical resistance ratings. Stacks are usually built per standards like BS4994/EN13121 or customer requirements. Flanges and bases are designed for easy bolting (as per ASTM D3972 or DIN standards).

Unique Selling Points

Key USPs include factory-made corrosion resistance and “no-leak” joints. For example, the largest FRP chimneys exceed 9m diameter and 30m height while maintaining structural integrity. Customers benefit from FRP’s custom engineering (tapered stack designs, multiple vents) and integrated features (rain caps, platforms). In summary, FRP chimneys deliver a maintenance-free exhaust solution that saves on painting, repairs and downtime over the stack’s lifetime.