Key Features

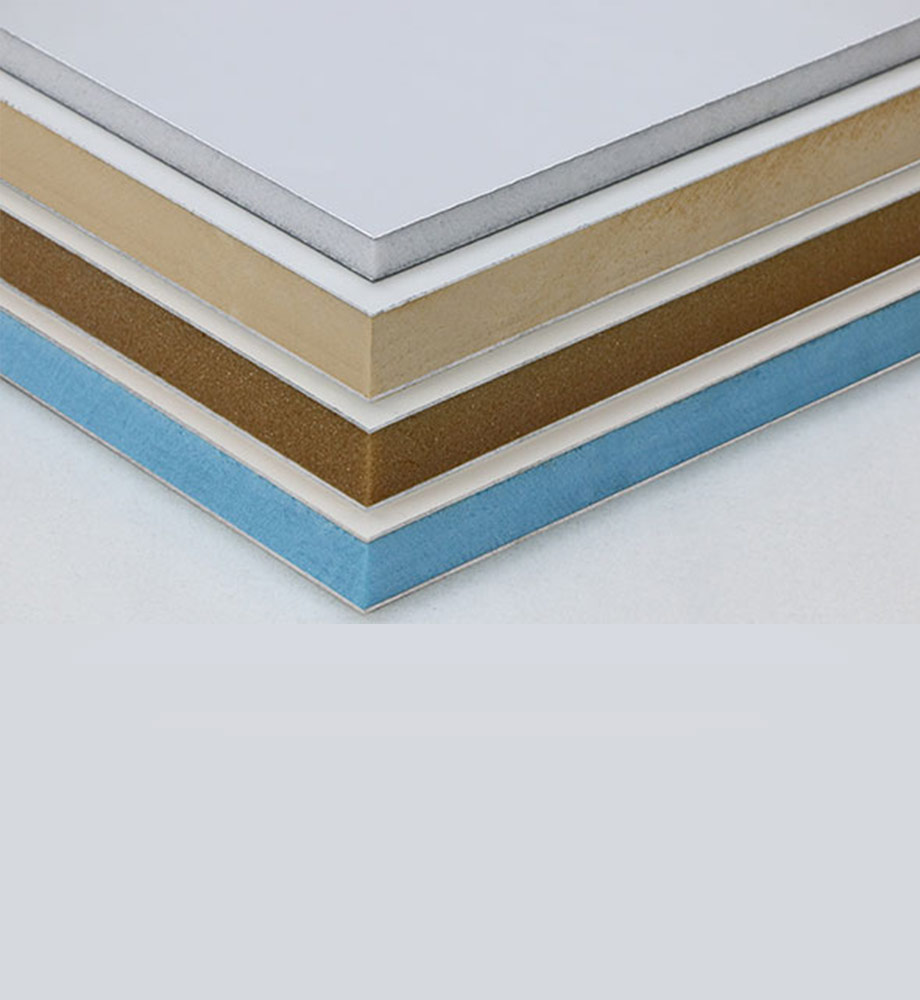

- Sandwich Construction: Thin strong skins laminate bonded to closed-cell foam core creates a panel much stiffer than a single-skin laminate.

- High Strength-to-Weight: Panel can support loads far beyond its weight. “Sandwich core composites offer higher strength-to-weight ratios than solid composite laminates alone”.

- Thermal & Sound Insulation: Foam core adds insulating properties, reducing heat transfer and noise.

- Dimensional Stability: Resists warping over large surface areas; retains flatness.

Benefits

- Structural Efficiency: Significantly lighter than solid or metal panels while achieving similar load capacity.

- Design Freedom: Can fabricate large sheets up to 3–4 m wide, then cut or trim on site.

- Fire Performance: With appropriate foam and skin selection, panels meet stringent flame-spread ratings.

- Corrosion Resistance: Entire panel is non-metallic and resists moisture ingress.

Applications

- Transmitter and data center rooms (bulkheads, floors).

- Machine access floors, ceilings, and clean room walls.

- Rail car interiors and signs where weight saving is crucial.

- Solar panel support substrates (light and rigid).

Technical Specifications

- Skin Material: E-glass or carbon fibers in polyester, vinylester, or epoxy resin.

- Core Material: PMI (e.g. Rohacell), PVC, or PU foam (density 40–150 kg/m³).

- Panel Thickness: Typically 6–50 mm core; overall thickness 8–52 mm.

- Sizes: Common lengths up to 12 m, widths up to 2.4 m (laminating jig limits).

Unique Selling Points (USPs)

- Maximized Payload Efficiency: Foam panels excel when every kilogram matters (e.g. aerospace, transportation).

- No Core Crush: Closed-cell foam resists water absorption and crush, unlike honeycomb cores.

- Fast Fabrication: Pultruded foam panels can be rapidly cut and bonded on site.