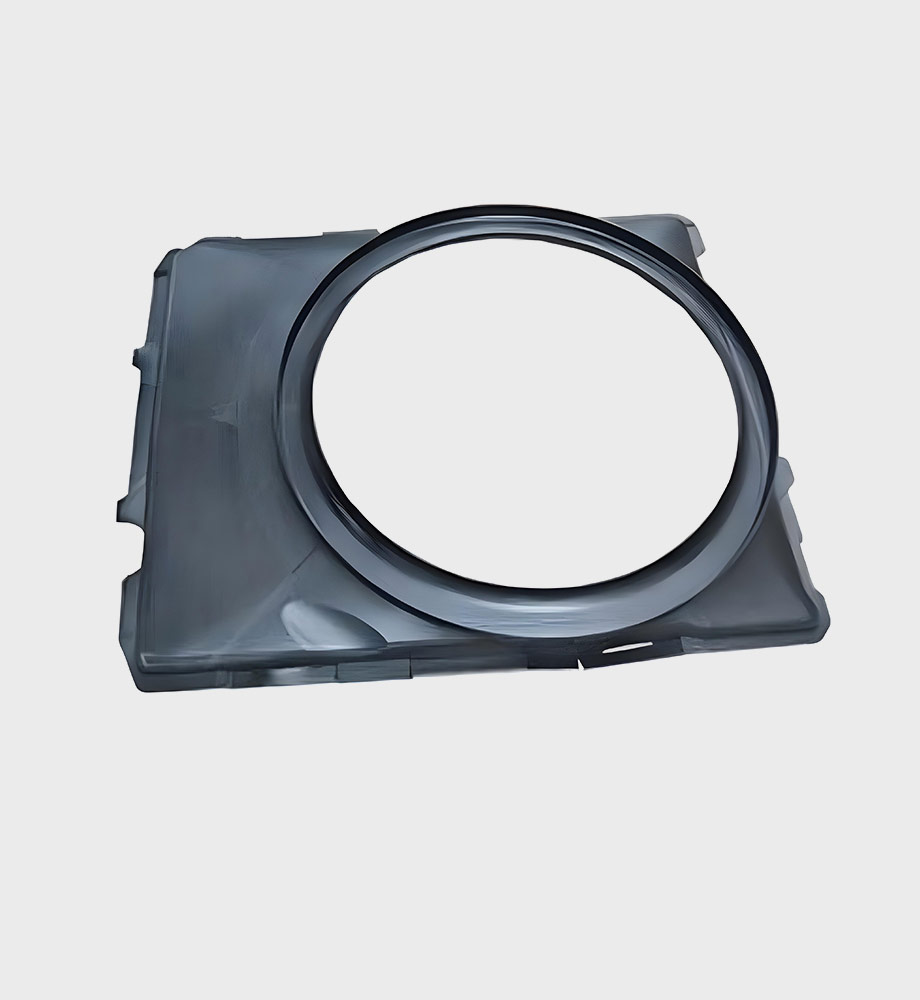

Key Features

- Fabricated pultruded or filament-wound FRP cylinder sections. Designed for high structural rigidity to withstand wind and internal pressure. Typically include mounting flanges and access doors. UV-stable resins prevent degradation from sunlight. Can be custom-flared for specific airflow patterns.

Benefits

- Improves fan efficiency by channeling air and recovering velocity (lowering required horsepower). Reduces noise and vibration by smoothing airflow and shielding rotating blades. Protects personnel by creating a solid barrier around the fan. FRP construction provides high strength under wind load (one manufacturer’s shrouds rated for up to 120 mph winds). No corrosion or wood decay issues in the tropical outdoor environment.

Applications

- Installed on the intake or fan deck of crossflow and counterflow cooling towers. Supports airflow in open-topped towers as well as closed-cycle towers. Also used as fan housings in industrial ventilation.

Technical Specifications

- Standard fan cylinders come in diameters from 3 to 10 meters and heights of 1–2 meters. Panels are often 50–75 mm thick and laminated in segments. Stress analysis ensures safety under specified wind and mechanical loads. UL or ISO ratings for FRP material may apply.

Unique Selling Points (USPs)

- As one vendor notes, “Fan cylinders are crucial components for protecting fan blades, minimizing sound and vibration, and facilitating optimal fan performance”. FRP cylinders are lightweight yet extremely strong, offering lower maintenance than steel (no repainting) and better safety (no rust fragments). They extend fan life and improve overall tower performance.