Key Features

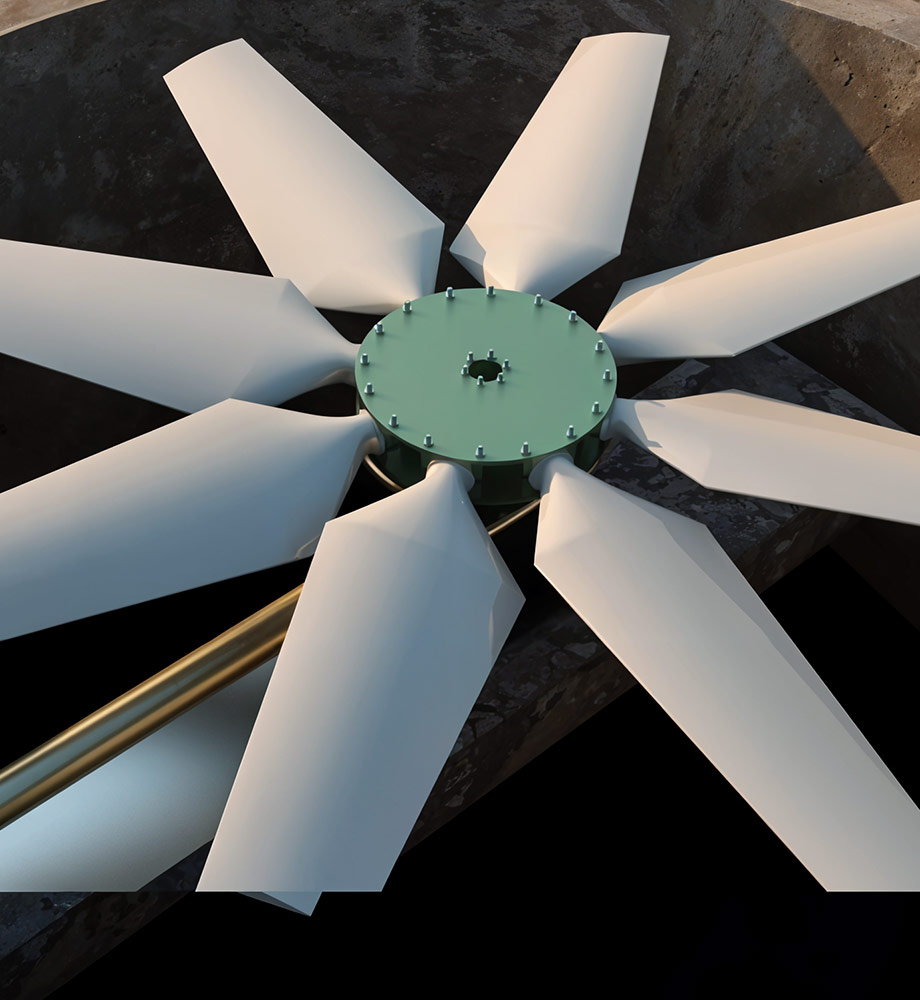

- Aerodynamic FRP composite blades, often pultruded or molded with multi-axial glass fiber. Highly corrosion-resistant resin (e.g. vinyl ester) to withstand moisture and chemical exposure. Lightweight (typically 1/5th the weight of steel) for reduced inertia. Precision-balanced with low vibration.

Benefits

- Efficient airflow: the stiff FRP maintains exact blade pitch and shape under load, maximizing fan performance. Lower energy consumption due to lighter rotating mass. Excellent durability – blades will not rust, warp, or delaminate in service. Reduced noise and vibration, leading to quieter tower operation. Easier and safer handling during maintenance (lighter, non-magnetic).

Applications

- Forced draft or induced draft cooling towers in power plants, chemical plants, HVAC systems, and industrial facilities. FRP blades are the norm for large-diameter cooling fans (typical diameters 5–9 m), as well as smaller fans in modular towers.

Technical Specifications

- FRP fan blades commonly have tensile strengths over 800 MPa and a laminate thickness from 10–20 mm. Blade lengths and airfoil profiles are optimized for each fan diameter and speed. Fire retardant grades can be specified per safety requirements.

Unique Selling Points (USPs)

- Proven longevity in corrosive environments – FRP blades “become the standard material for cooling tower blades due to [their] great strength to weight ratio and resistance to corrosive elements”. They outperform traditional wood or metal blades in both lifespan and safety, reducing the risk of catastrophic failure.