Key Features

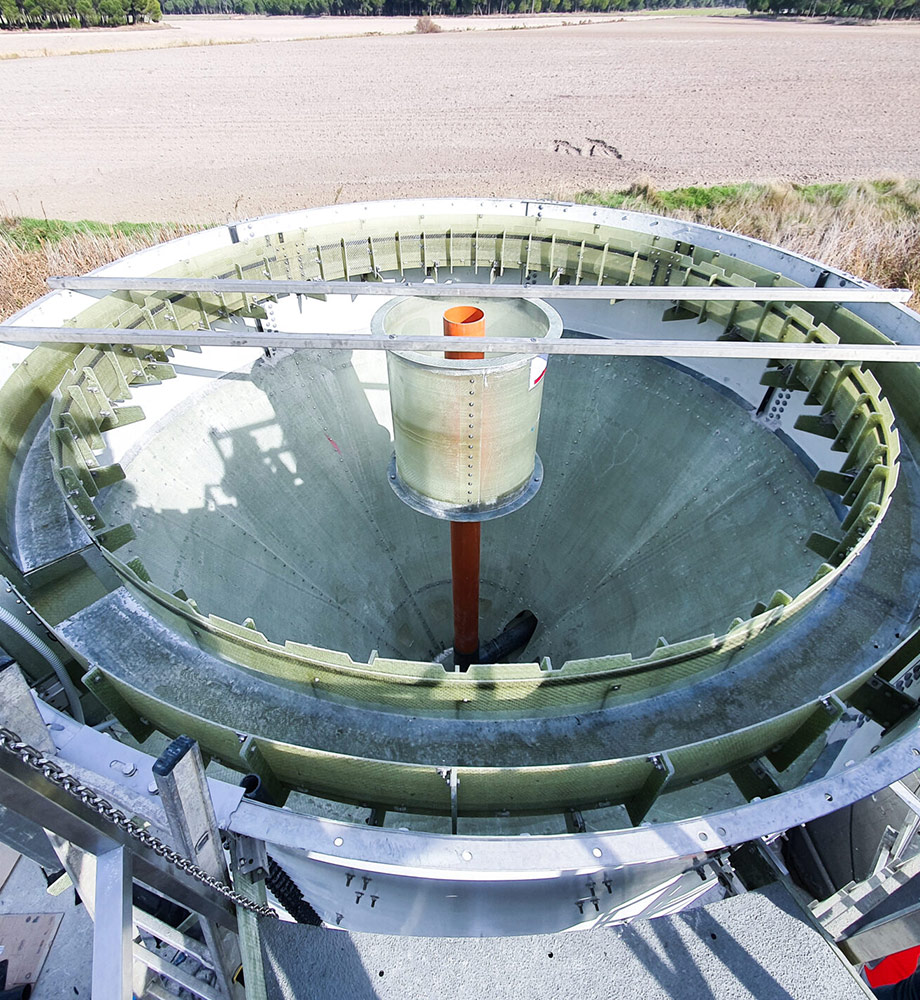

- Durable FRP Construction: 100% fiberglass-reinforced plastic tank body resists corrosion from acids, alkalis and bacteria.

- High Strength-to-Weight: Pultruded FRP walls and beams provide rigidity with minimal dead load. Laminated layers (e.g. 24 oz woven roving) make troughs up to 50% stronger than conventional units.

- Custom Design: Available in multiple sizes, shapes and materials (isophthalic or vinyl ester resin); lamella packs built to client-specified plate angle and pitch. Weirs (V-notch, straight, sharp-crested, etc.) and launders integrate seamlessly.

- Precision Fabrication: FRP panels and splice plates produced in-house for uniform quality. Tanks comply with relevant standards (e.g. AWWA D120-type FRP storage tank code).

Benefits

- Efficient Solids Removal: Enhanced settling efficiency (especially lamella clarifiers) yields clear effluent with minimal footprint.

- Corrosion Resistance: FRP construction prevents rust and chemical attack, ensuring long life even with industrial effluent.

- Cost-Effective: Lightweight FRP reduces installation and foundation costs. Flat-panel assembly speeds construction. Custom fabrication means minimal field welding.

- Low Maintenance: Smooth FRP surfaces inhibit bio-fouling; our clarifiers require little upkeep and resist UV degradation.

Applications

Municipal and industrial wastewater treatment, primary and secondary settling, process water clarification in chemical plants, food & beverage, pharmaceuticals, pulp & paper, mining and more.

Technical Specifications

Sizes range from small modular units to large-diameter tanks (1 m³ to >50,000 m³). Wall thickness and reinforcement are engineered per design loads. Lamella plates typically angled ~60° with spacing 50–70 mm. Weir plates are 5–12 mm FRP with stainless hardware. Clarifier capacities, flow rates and HRT are custom-calculated.

Unique Selling Points

Fully engineered FRP clarifier systems with in-house design, advanced resin systems (e.g. NSF-61 compliant options), and optional features (covers, mixers, sludge hoppers). Compared to concrete or steel, our FRP clarifiers offer longer service life, zero corrosion, and easier retrofit of existing plants.