Key Features

- Glass-Polyester Construction: Casings are made from glass-fiber reinforced resin (a thermoset composite). This material provides excellent mechanical strength and electrical insulation.

- Arc-Quenching Design: Internal shape directs arcs into quenching chambers, but the outer housing contains any flashes.

- Flame Resistance: The composite casing is self-extinguishing, meeting UL 94 V0 criteria in many cases.

- Integrated Busway Interface: Often includes molded slots or connections for busbars and panel mounting.

Benefits

- Electrical Isolation: Prevents short circuits between phases and to the ground – the glass-polyester ensures leakage currents are negligible.

- Durability: Resistant to impact and thermal cycling; maintains integrity even under fault conditions.

- Safety: Keeps live contacts safely enclosed; many designs are touch-safe on the outside.

Applications

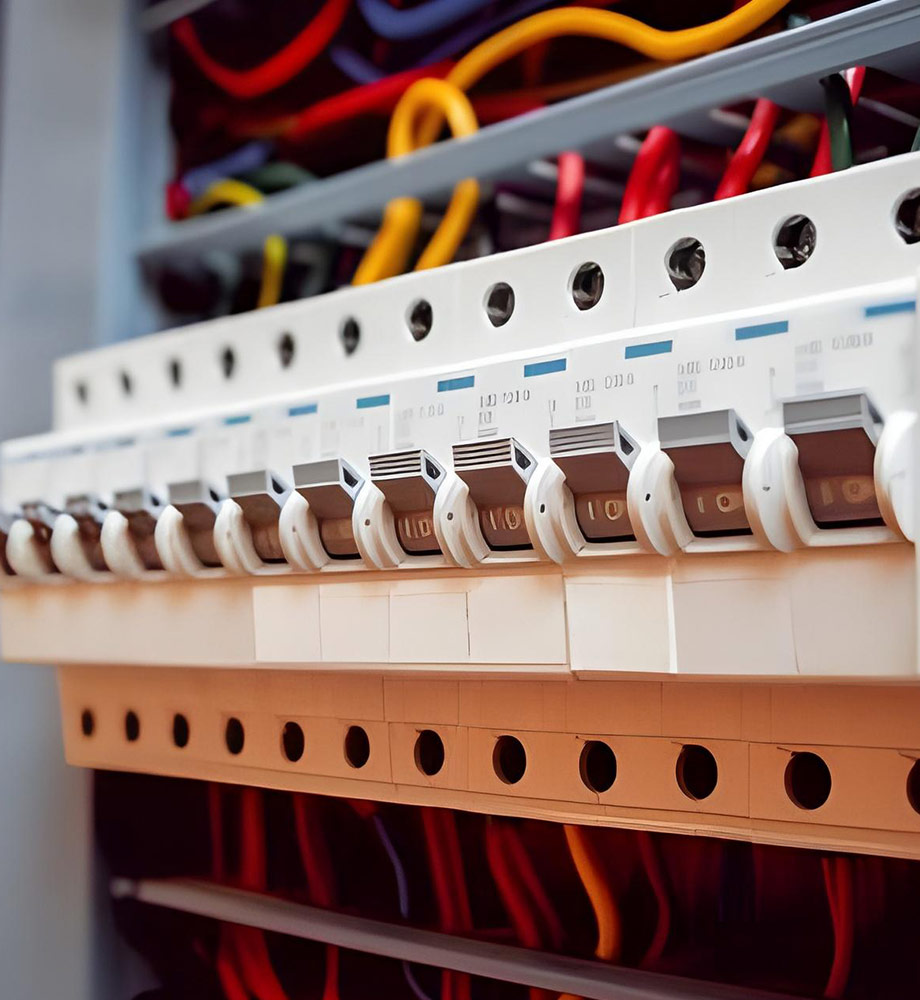

- Low-Voltage Switchgear: Houses for molded-case circuit breakers (MCCBs) and miniature circuit breakers (MCBs) in electrical panels.

- Motor Control: Enclosures for motor protector breakers in control panels and motor starters.

- Distribution Panels: Main breaker enclosures in switchboards or distribution boxes.

Technical Specifications

- Material: Glass-polyester thermoset (often reinforced with 20–40% glass fiber).

- Voltage Rating: Up to 1000 V in many MCCB designs.

- Standards: Insulation must meet IEC 60695 and UL 489, including impulse and tracking resistance.

- Temperature Range: Typically –40°C to +85°C for standard housings.

Unique Selling Points (USPs)

- Composite Strength: The special glass-resin mix endures electrical arcing stresses and keeps electronics isolated.

- Compact Safety: Enables compact breaker designs by combining structural support and insulation in one molded part.