Key Features

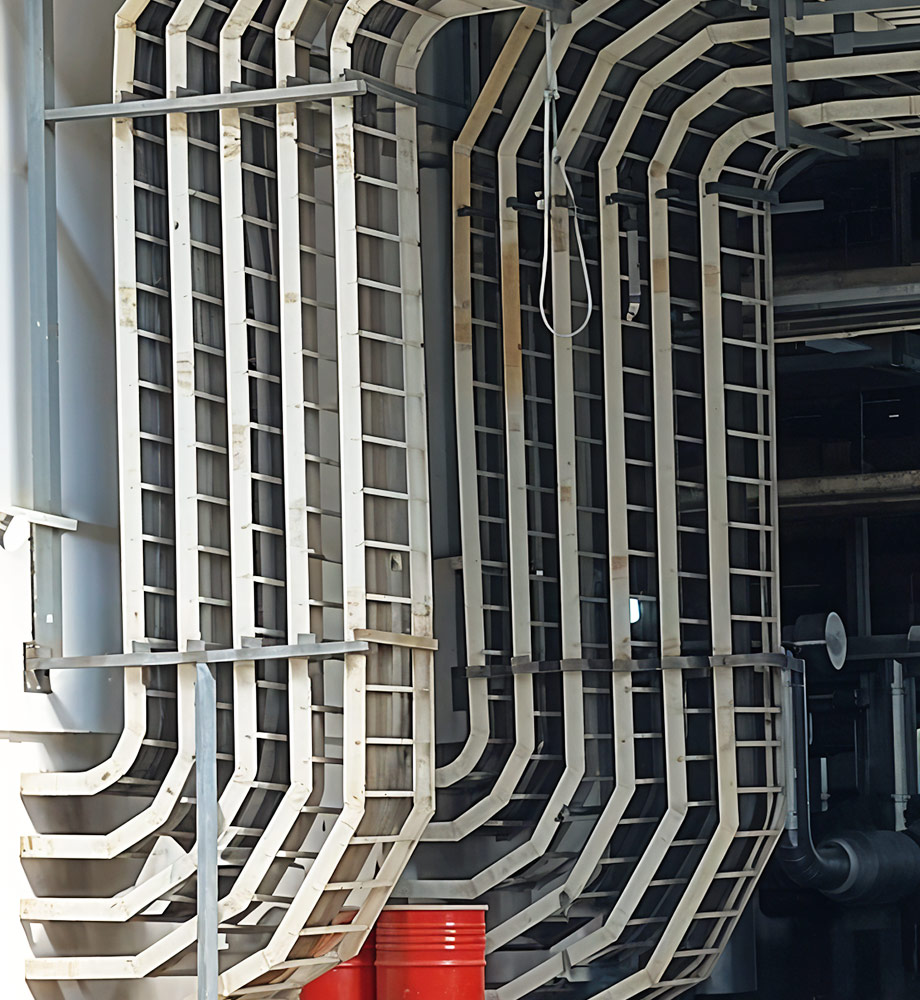

- Pultruded FRP Construction: High-quality fiberglass profiles and crossbars, pultruded for uniform strength.

- Corrosion Resistance: Inherent immunity to rust and corrosion, ideal for marine/offshore and coastal wind farms.

- Modular Design: Sectional design with standard widths (e.g. 100–400 mm) and depths (50–80 mm) for easy field assembly.

- Variety of Styles: Ladder trays with rung spacing for large cables; solid/ventilated channel trays for small cables or pneumatic tubing.

- Fire-Retardant: Standard UL-94 V-0 materials; optional high-temp resins for specific fire codes.

Benefits

- Lightweight: Up to 80% lighter than steel, easing installation and reducing load on structures.

- High Strength-to-Weight: Can support heavy cable bundles without sagging (fiberglass trays have excellent rigidity).

- Low Maintenance: Once installed, FRP trays require virtually no upkeep.

- Safety: Non-magnetic and non-conductive, reducing interference and eliminating corrosion hazards.

Applications

- Routing power and communications cables inside turbine towers, on turbine platforms, and in wind farm substations. Commonly used in offshore turbine bases, onshore turbine foundations, and electrical control buildings. Also suitable for supporting instrumentation and hydraulic lines (as noted, fiber trays even handle pneumatic tubing).

Technical Specifications

- Our FRP cable trays meet stringent testing. They can be supplied in any length up to 12 m or longer (spliced). Standard load ratings per UL 870 (for trays) are easily met due to high GRP strength. Typical span (unsupported) is ~1.2–1.5 m for ladder trays. FRP panels are rated for UL Standards and come with NEMA fiberglass finish.

Unique Selling Points (USPs)

- We offer the industry-standard Enduro® FRP cable tray system, proven in offshore installations. Our trays are manufactured under strict quality control; as noted by Creative Composites, they “undergo world-class quality testing” to ensure performance. With decades of experience, we can provide any configuration (ladder, channel, tiered systems) and complete accessories (covers, splices, fittings). By using FRP cable trays, our customers get a long-lasting cable support solution with the best total cost of ownership.