Key Features

- Corrosion-Free FRP: Completely non-metallic, preventing rust even in saltwater or chemical-laden environments.

- High Load Capacity: Lightweight structure yet designed to support heavy cable bundles; long spans between supports possible.

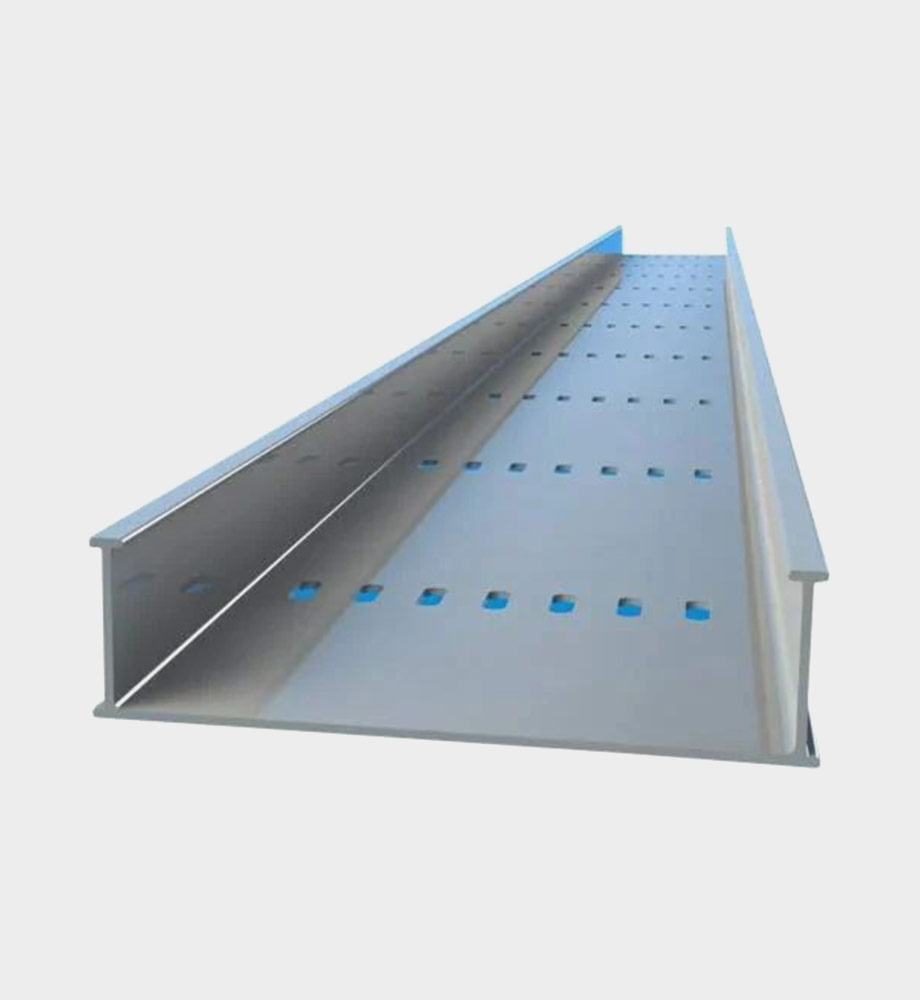

- Open-Tray Design: Supports air circulation and water drainage around cables, reducing heat buildup.

- Rigid Covers: Optional FRP covers lock onto tray for protection against debris, moisture, and unauthorized access.

- Fire-Resistant Construction: Long fire stops or intumescent coatings can be applied for required flame ratings.

Benefits

- Simplified Maintenance: Cable pulling & rerouting is easy — pull cables into position on open tray instead of through conduit.

- Electrical Safety: Insulating material eliminates risk of short circuits or earth faults through the support structure.

- Longevity: Withstands harsh chemicals and extreme weather with virtually no degradation; ideal for tunnels and outdoor substations.

- UV and Thermal Stability: UV-stabilized resins keep trays stable under sun exposure; handles temperature variation without brittleness.

Applications

- Indoor and outdoor cable support at railway signal rooms and substation panels

- Cable raceways in tunnels and elevated guideways

- Cable routing along platform edges and station mechanical rooms

- Any rail electrification projects requiring secure, organized wiring

Technical Specifications

- Material: Glass-fiber-reinforced polyester or vinylester; conductive-free

- Sizes: Standard widths 50–200 mm, heights 20–100 mm; lengths up to 6 m

- Accessories: Bends (90° inside/outside), Tees, Reducers, Splice plates, mounting clamps

- Finish: Smooth inner surface for cable protection; UV-black or gray exterior for UV protection

Unique Selling Points (USPs)

- Electrical Insulation: Unlike steel trays, FRP channels do not conduct, ensuring user safety and ease of grounding

- Versatile System: Full range of fittings enables a “complete cable tray system” suited for rail environments

- Future-Proof: Easy access for adding future cables (“accessibility for future”) without major work