Cladding Support

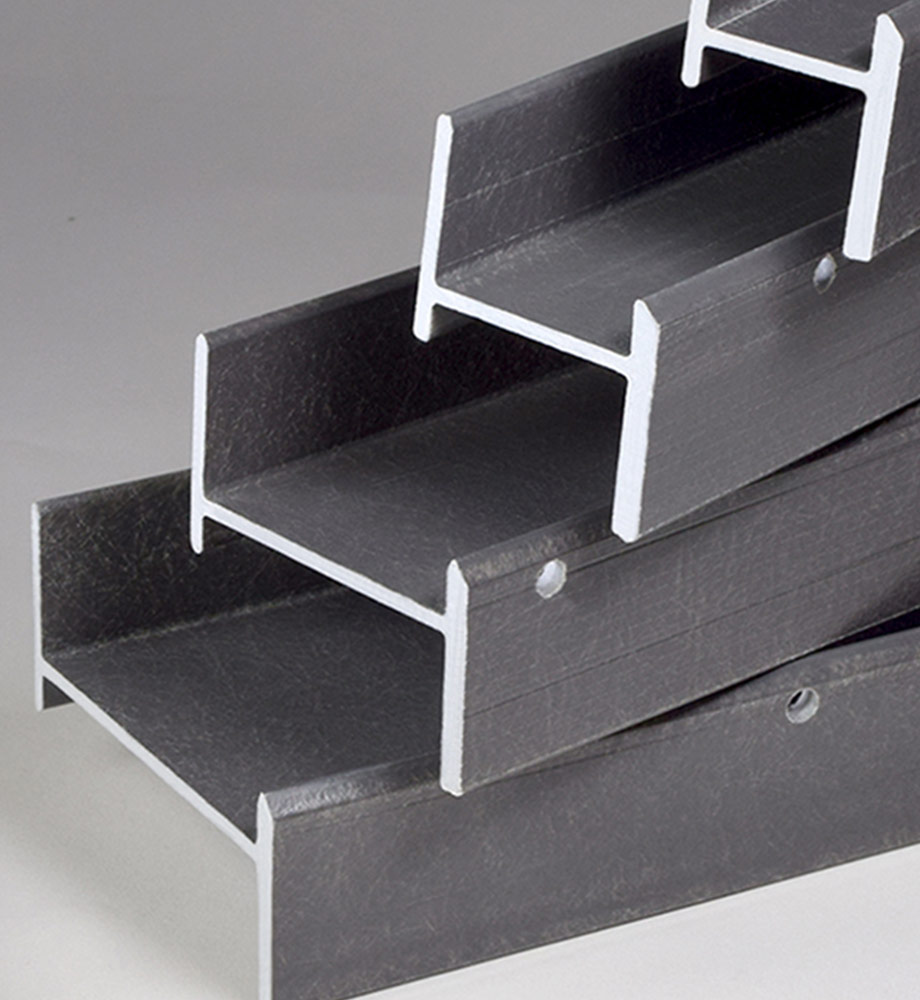

FRP Cladding Support Systems consist of pultruded FRP beams and attachment rails designed for ventilated façades and curtain walls. These all-composite supports eliminate thermal bridging (continuous insulation), are non-corrosive, and carry heavy cladding loads. Strongwell’s STRONGIRT system, for example, uses a fire-retardant FRP channel that offers “superior pullout strength, excellent thermal efficiency” for exterior cladding. The support profiles are engineered for rigidity and incorporate self-draining geometry to handle rain. An all-FRP design means no metal parts to rust, even in marine or polluted environments.

Product Inquiry