Key Features

- Superior Properties: High tensile and flexural strength with excellent heat and chemical resistance.

- Eco-Friendly: Produced from natural basalt ore without additives; no toxic fumes in manufacture.

- Corrosion-Proof: Better chemical stability than E-glass; suitable for acids, alkalis, and high-humidity environments.

- Non-Magnetic/Electrically Insulating: Naturally so, like standard FRP.

Benefits

- Longer Durability: Outperforms glass in high-temperature or corrosive settings (e.g. up to 550°C before softening).

- Cost-Effective Upgrade: Often competitive in price with high-end fiberglass, yet provides higher strength and stability.

- High Stiffness: Offers a slight stiffness improvement over E-glass, allowing slimmer sections.

Applications

- Electrical components (insulating supports, cable ties) where higher thermal endurance is needed.

- Marine and offshore structures (deck framing, supports) exposed to saltwater.

- Oil & gas (floor gratings, handrails in chemical plants).

- Pultruded cross-arms and supports on power distribution lines (replacing glass where chemicals are present).

Technical Specifications

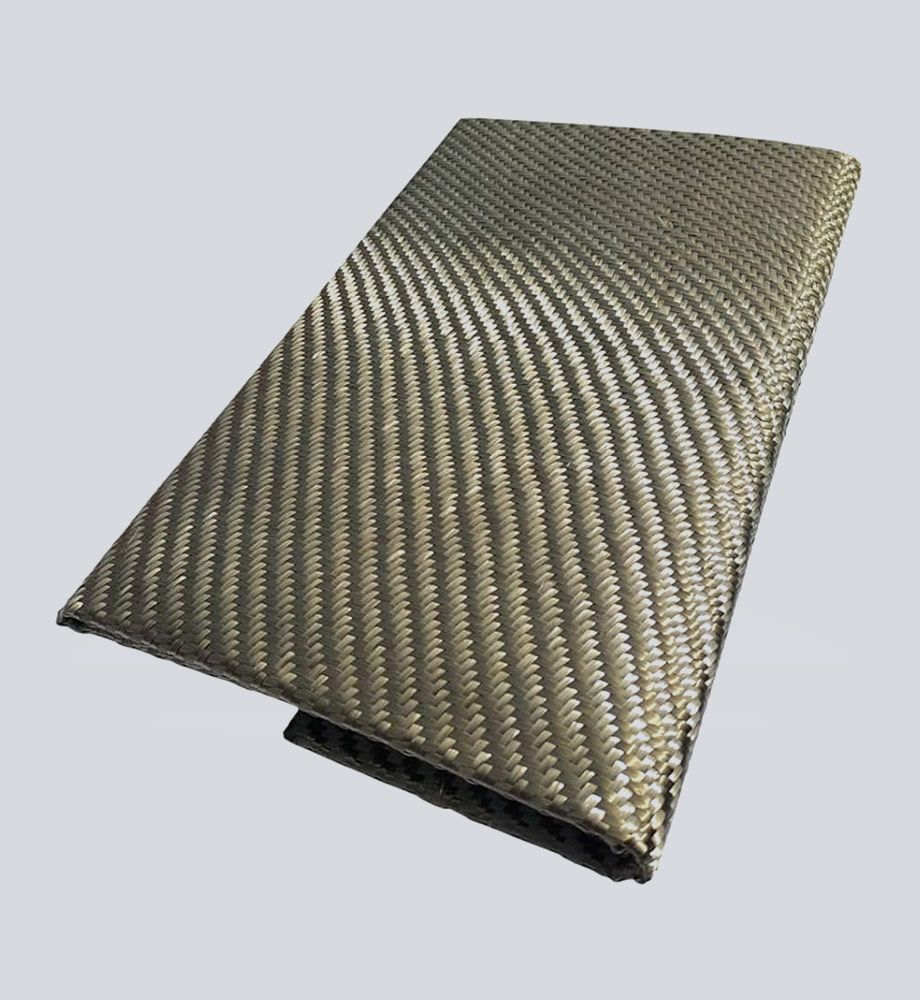

- Material: Basalt fiber cloth or roving with vinylester resin (high-temp resins can be used).

- Typical Profiles: Basalt U-channels, T-sections, flat bars, and round rods in standard dimensions.

- Mechanical: Tensile modulus ~20–40 GPa, tensile strength 1.0–2.5 GPa. Superior to many glass formulations.

- Standards: Often rated for high fire performance (UL 94 V-0 possible) due to basalt’s mineral nature.

Unique Selling Points (USPs)

- Highest Thermal Limit of FRP: Basalt composites remain stable at temperatures exceeding those glass can handle.

- Enhanced Stability: Less thermal expansion and higher creep resistance than glass, leading to tighter dimensional stability.

- “Green” Fiber: Derived from abundant natural rock, offering environmental branding value.